Over 80 years of detailed experience: Hwacheon combines traditional craftsmanship with modern technology. Our expertise in machine tool manufacturing ensures high production quality and continuous innovation for future-proof concepts in the German market.

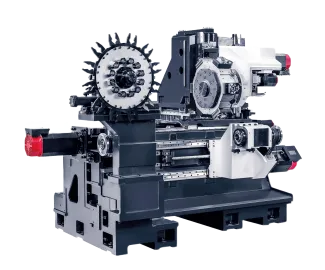

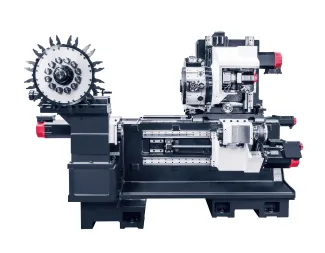

C1

Category

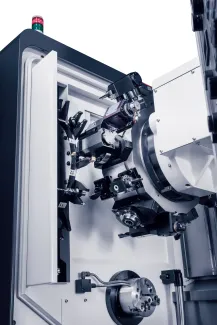

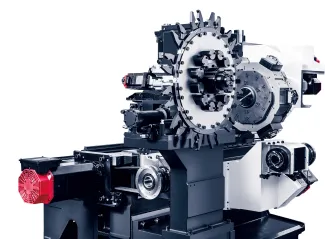

Multitasking LathesMachine series

C - BaureiheAvailable with

- Siemens 828D

- Fanuc 0i Plus

Size of C1

| Max. cutting diameter | mm | 530 - 630 | |

| Chuck-Size | mm | 155 - 200 | |

| Swing over bed | mm | 730 | |

Tradition Meets Modernity

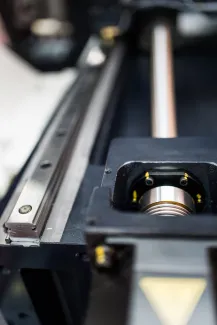

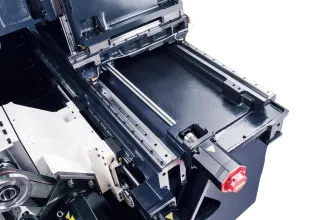

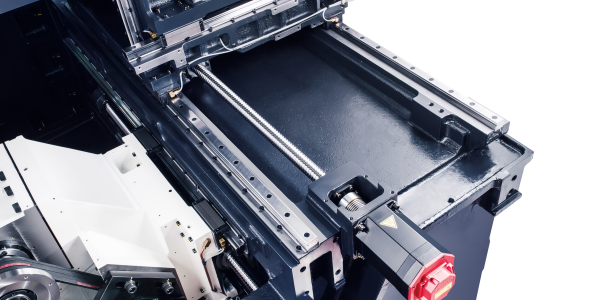

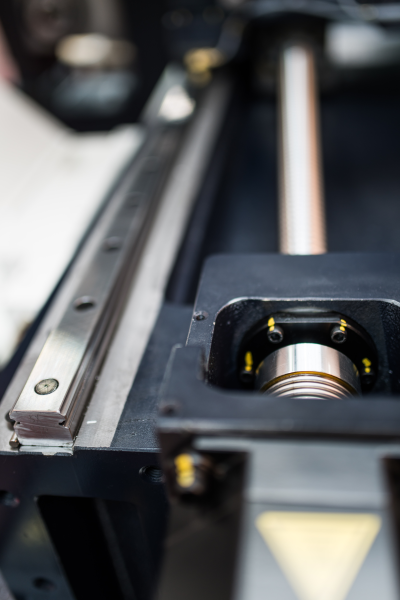

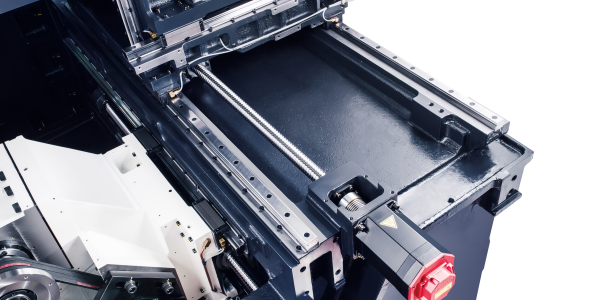

Dynamic Linear Guides

Speed and Dynamics Combined: Linear roller guides provide high dynamics and rapid traverse speeds. The workpiece weight is transferred linearly to the rollers, which must withstand enormous pressure at contact points. Therefore, we exclusively use linear roller guides from renowned manufacturers.

Why choose us?

Performance in Focus

Power for your production: Our machines are designed for maximum productivity and availability. Top-class engineering and craftsmanship provide you with a crucial competitive advantage – all for your business success.

Future-Proof Solutions

Innovation in every machine: State-of-the-art technologies shape our machine concepts, based on the latest standards for turning and milling machines. You benefit from efficient solutions, customized to your requirements.

Technical Data

| Item | Unit | C1 | C2 |

|---|---|---|---|

| Axis-Stroke (X / Y / Z) | mm | 310 / 100 / 700 | 360 / 120 / 700 |

| Spindle power | kW | 11 / 7.5 | 15 / 11 |

| Spindle speed | rpm | 6000 | 5000 |

| Rapid speed | m/min | 30 / 15 / 30 | |

| Tool shank | BMT-55 / C4 | ||

| Number of tools | 18 + 12 | ||

| Machine weight | kg | 10500 | 10800 |

| Max. cutting diameter | mm | 530 | 630 |

| Max. cutting length | mm | 599 | 564 |

| Chuck-Size | mm | 155 | 200 |

| Swing over bed | mm | 730 | |

| Max. Bar size | mm | 51 | 65 |

| Sub spindle speed | rpm | 6000 | |

| Sub spindle motor power | kW | 7.5 / 5.5 | 15 / 11 |

| Coolant tank vol. | Liter | 200 | 230 |

| Spindle torque | Nm | 0 | 477 / 233 |

Configurations

| Y | MC | S | |

|---|---|---|---|

| C1 | Std. | Std. | Optional |

| C2 | Std. | Std. | Optional |

Features of C1

Dynamic Linear Guides

Speed and Dynamics Combined: Linear roller guides provide high dynamics and rapid traverse speeds. The workpiece weight is transferred linearly to the rollers, which must withstand enormous pressure at contact points. Therefore, we exclusively use linear roller guides from renowned manufacturers.

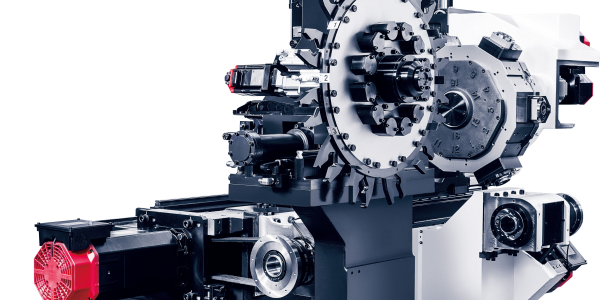

Y-Axis

Greater Flexibility and Time Savings: Lathes with a Y-axis enable 3-axis interpolation movements and the creation of off-center bores and milling operations. This allows workpieces to be fully machined in a single setup, eliminating operations on other machines and increasing machining accuracy. Additionally, they optimize grooving and parting processes by reducing lever forces for faster workflows.

| Item | Unit | C1 | C2 |

|---|---|---|---|

| Axis-Stroke (X / Y / Z) | mm | 310 / 100 / 700 | 360 / 120 / 700 |

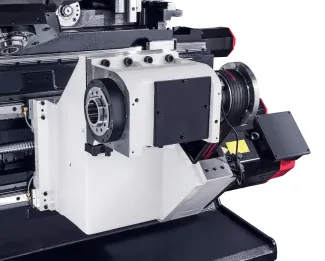

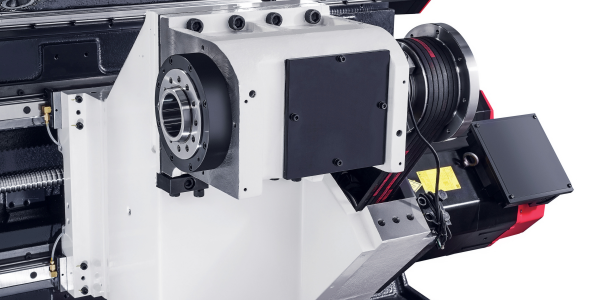

Counter Spindle

Precision in Every Dimension: Lathes with a counter spindle enable back-side machining of workpieces and can alternatively be used as an NC tailstock. This back-side machining saves time and effort by eliminating the need for re-clamping on another machine. It also improves precision since the workpiece does not need realignment. For enhanced process stability and safe ejection of finished workpieces, optional pneumatic or mechanical ejectors and spindle flushing can be added.

| Sub spindle speed | rpm | 6000 | |

| Sub spindle motor power | kW | 7.5 / 5.5 | 15 / 11 |

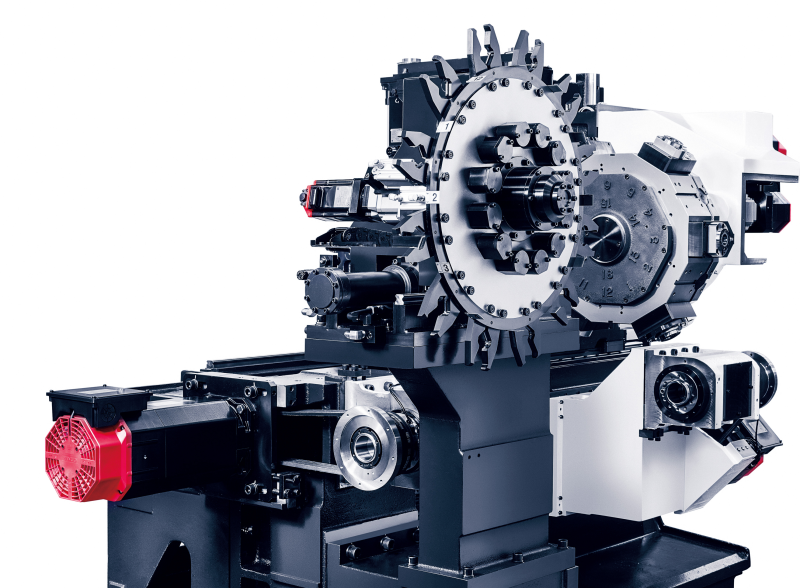

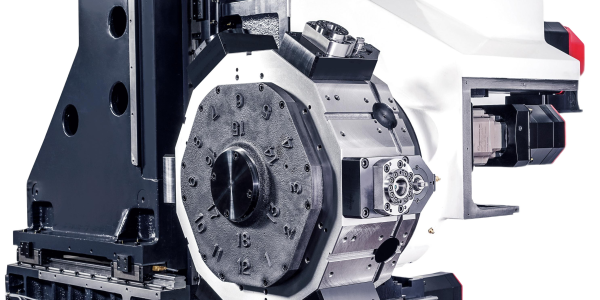

Turret

| Tool shank | BMT-55 / C4 | ||

| Number of tools | 18 + 12 | ||

Clamping Technology

| Chuck-Size | mm | 155 - 200 | |

Automatic Tool Changer

| Tool shank | BMT-55 / C4 | ||

| Number of tools | 18 + 12 | ||

Driven Tools

Precision and Versatility Combined: Driven tools on lathes significantly expand machining capabilities. They enable milling, drilling, and other processes directly on the lathe, reducing re-clamping operations and minimizing downtime. Using various tools in a single setup increases machining accuracy and boosts overall productivity.

Internal Coolant Supply

ICS Makes the Difference!: The internal coolant supply (ICS) delivers coolant directly to the cutting edge, optimizing lubrication and chip removal. It boosts productivity, extends tool life, and enhances process reliability.

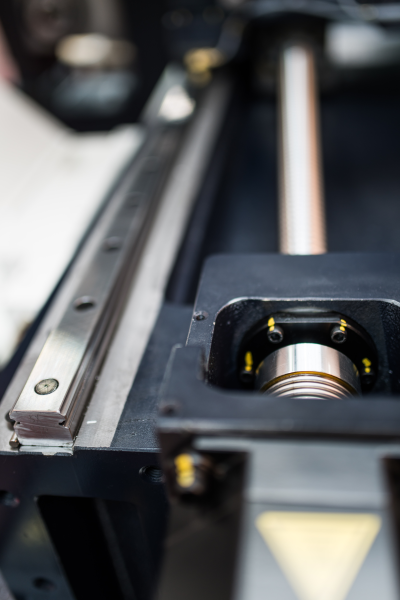

High-Quality Pretensioned Ball Screws

Thermal Stability for Precision and Reliability: Pretensioned ball screws reliably and stably compensate for thermal expansion. This technology prevents unwanted elongation of the spindles, ensuring lasting precision and consistently high machining accuracy over extended operating periods.

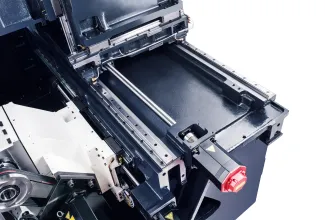

Excellent Chip Disposal

Perfect Chip Removal for Your Machine!: Our innovative chip disposal systems reliably remove chips, reduce heat, and optimize machining. High-quality components ensure uninterrupted operation and maximum process reliability.

- Coolant tank vol.200Liter

- Coolant tank vol.230Liter

Other features and options

BMT-55 / VDI-30, Extra Tool Magazin, Belt-Driven Spindle, Tailstock, Parts catcher, Siemens 828D, Fanuc 0i Plus, Chip Conveyor, Work table, Workspace, Tool measuring, Peripherals and accessories, Machine SizeC1

| Max. cutting diameter | mm | 530 - 630 | |

| Chuck-Size | mm | 155 - 200 | |

| Swing over bed | mm | 730 | |

C2

| Max. cutting diameter | mm | 530 - 630 | |

| Chuck-Size | mm | 155 - 200 | |

| Swing over bed | mm | 730 | |