Over 80 years of detailed experience: Hwacheon combines traditional craftsmanship with modern technology. Our expertise in machine tool manufacturing ensures high production quality and continuous innovation for future-proof concepts in the German market.

CUTEX-160

Category

Universal LathesMachine series

CUTEX-BaureiheAvailable with

- Siemens 828D

- Fanuc 0i Plus

Size of CUTEX-160

| Chuck-Size | mm | 155 - 200 | |

| Max. cutting diameter | mm | 300 | |

| Swing over bed | mm | 550 | |

Tradition Meets Modernity

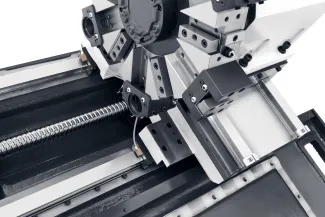

Dynamic Linear Guides

Speed and Dynamics Combined: Linear roller guides provide high dynamics and rapid traverse speeds. The workpiece weight is transferred linearly to the rollers, which must withstand enormous pressure at contact points. Therefore, we exclusively use linear roller guides from renowned manufacturers.

Why choose us?

In-House Quality

Quality is created here: With our own manufacturing depth, including foundry and spindle production, we ensure durable and reliable machines. Quality and control go hand in hand to meet the German standards.

Tailor-Made

Flexibility is key: With extensive customization options, we design machines that exactly match your application. This gives you precise solutions for maximum efficiency and productivity in your business.

Technical Data

| Item | Unit | CUTEX-160A | CUTEX-160B |

|---|---|---|---|

| Axis-Stroke (X / Y / Z) | mm | 170 / - / 335 | |

| Spindle power | kW | 15 / 11 | |

| Spindle speed | rpm | 6000 | 4500 |

| Spindle torque | Nm | 127 / 93 | 170 / 125 |

| Rapid speed | m/min | 36 / - / 36 | |

| Tool shank | none | BMT-55 / BH | |

| Number of tools | none | 12 | |

| Machine weight | kg | 3200 | |

| Max. cutting diameter | mm | 300 | |

| Max. cutting length | mm | 300 | 284 |

| Chuck-Size | mm | 155 | 200 |

| Swing over bed | mm | 550 | |

| Max. Bar size | mm | 45 | 51 |

| Coolant tank vol. | Liter | 81 | |

Configurations

| Y | MC | S | |

|---|---|---|---|

| CUTEX-160A | Optional | ||

| CUTEX-160B | Optional |

Features of CUTEX-160

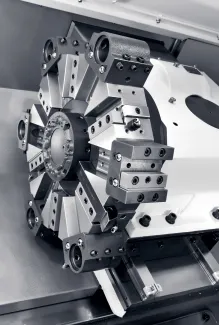

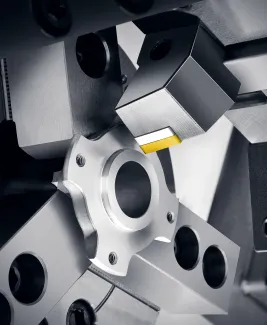

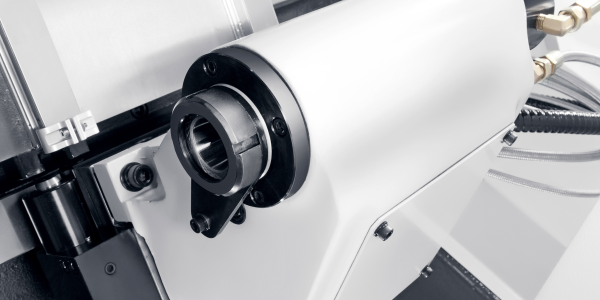

Turret

| Number of tools | none | 12 | |

| Tool shank | none | BMT-55 / BH | |

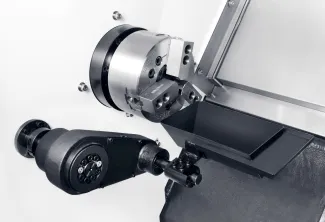

Tailstock

Dynamic Linear Guides

Speed and Dynamics Combined: Linear roller guides provide high dynamics and rapid traverse speeds. The workpiece weight is transferred linearly to the rollers, which must withstand enormous pressure at contact points. Therefore, we exclusively use linear roller guides from renowned manufacturers.

Tool measuring

Driven Tools

Precision and Versatility Combined: Driven tools on lathes significantly expand machining capabilities. They enable milling, drilling, and other processes directly on the lathe, reducing re-clamping operations and minimizing downtime. Using various tools in a single setup increases machining accuracy and boosts overall productivity.

Steady Rest Carriage

Stability for Precise Results: The steady rest ensures maximum precision for long workpieces through optimal support. It reduces vibrations, improves surface quality, and enables precise machining even for demanding projects.

Internal Coolant Supply

ICS Makes the Difference!: The internal coolant supply (ICS) delivers coolant directly to the cutting edge, optimizing lubrication and chip removal. It boosts productivity, extends tool life, and enhances process reliability.

High-Quality Pretensioned Ball Screws

Thermal Stability for Precision and Reliability: Pretensioned ball screws reliably and stably compensate for thermal expansion. This technology prevents unwanted elongation of the spindles, ensuring lasting precision and consistently high machining accuracy over extended operating periods.

Automatic Workpiece Changer

Autonomy and Efficiency Maximized: Automatic workpiece changers extend a machine’s unmanned operating time by independently changing workpieces without operator intervention. This supports multi-machine operation, optimizes cost-effectiveness, and maximizes machine utilization during extended operating periods.

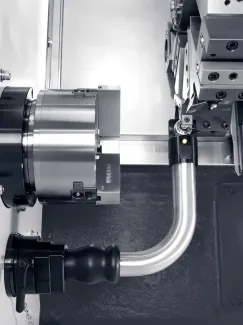

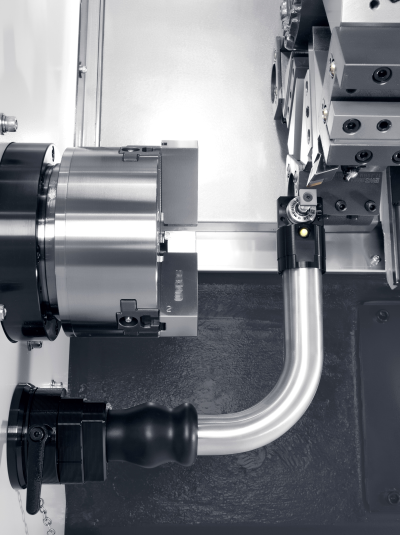

Excellent Chip Disposal

Perfect Chip Removal for Your Machine!: Our innovative chip disposal systems reliably remove chips, reduce heat, and optimize machining. High-quality components ensure uninterrupted operation and maximum process reliability.

- Coolant tank vol.81Liter

Other features and options

BMT-55 / VDI-30, Belt-Driven Spindle, Parts catcher, Clamping Technology, Siemens 828D, Fanuc 0i Plus, Chip Conveyor, Workspace, Peripherals and accessories, Machine SizeCUTEX-160

| Chuck-Size | mm | 155 - 200 | |

| Max. cutting diameter | mm | 300 | |

| Swing over bed | mm | 550 | |

CUTEX-180

| Chuck-Size | mm | 155 - 200 | |||

| Max. cutting diameter | mm | 350 | |||

| Swing over bed | mm | 700 | |||