Horizontal Machining Centers

Horizontal Machining Centers (Linear Roller Guides)

AF-4: Dynamics and Precision for Your Manufacturing

Discover the AF-4 – the perfect combination of innovative technology, high dynamics, and universal applicability.

Whether for machining steel, non-ferrous metals, or plastics: The AF-4 masters even the most demanding cutting conditions with impressive productivity.

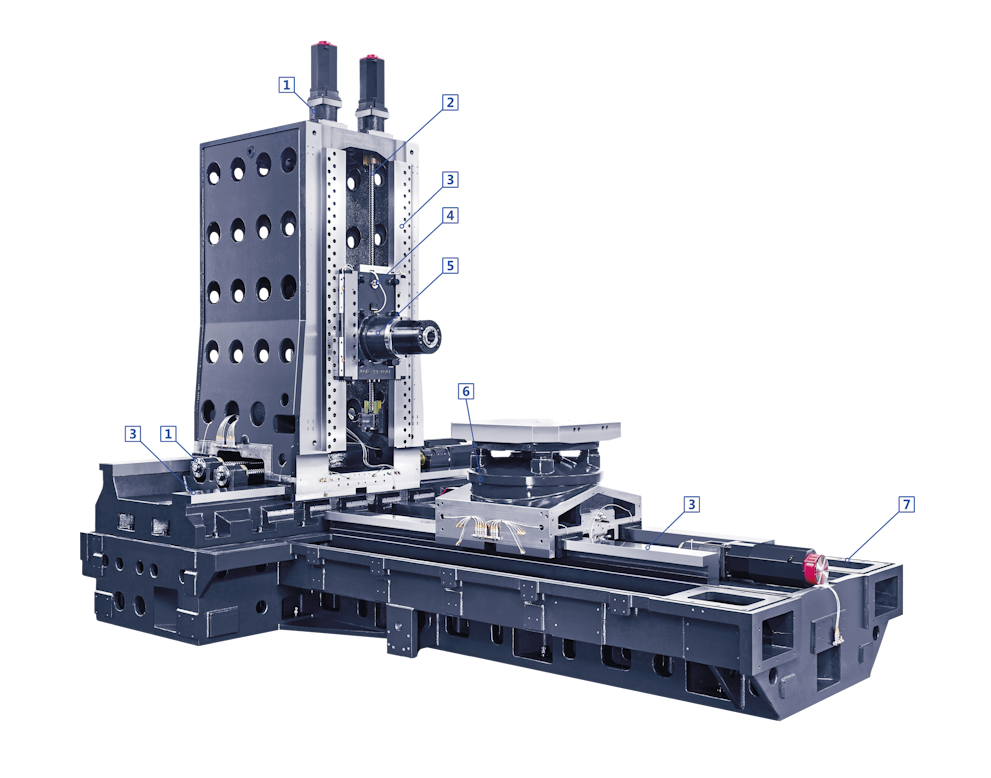

The AF-4 is a horizontal machining center that impresses with its compact design, high dynamics, and proven Hwacheon technology. Equipped with a 400-size pallet, linear roller guides, and in-house spindles, the AF-4 offers the ideal combination of speed, precision, and reliability – perfect for production-oriented manufacturing processes.

Compact, fast, and precise – The machine tool for maximum efficiency.

The AF-4 has been specifically designed for efficient and precise machining. Thanks to the fast positioning of the B-axis in just 1.4 seconds and a short chip-to-chip time of 4.6 seconds, it minimizes non-productive time.

The innovative oil-air aerosol cooling system extends the lifespan of the spindles and ensures a constant temperature – crucial for maximum accuracy, especially in the Z-axis. With rapid traverse speeds of up to 60 m/min and an expandable tool magazine, the AF-4 meets the highest demands for dynamics and flexibility.

- Linear roller guides: Dynamic and precise movements.

- In-house spindles:

- 15,000 rpm, 37 kW, 303 Nm torque.

- 20,000 rpm, 221 Nm torque.

- Both with BBT-40/HSK-A63 tool interface.

- Tool magazine: Standard with 40 slots, expandable to 60.

- B-axis: Fast 90° positioning in just 1.4 seconds.

- Tool changer: Chip-to-chip time of only 4.6 seconds.

- Rapid traverse speed: Up to 60 m/min.

- Cooled and preloaded ball screw spindles: For stability and precision.

- Oil-air aerosol cooling: Optimal spindle temperature and extended lifespan.

Horizontal Machining Centers (Flat Guides)

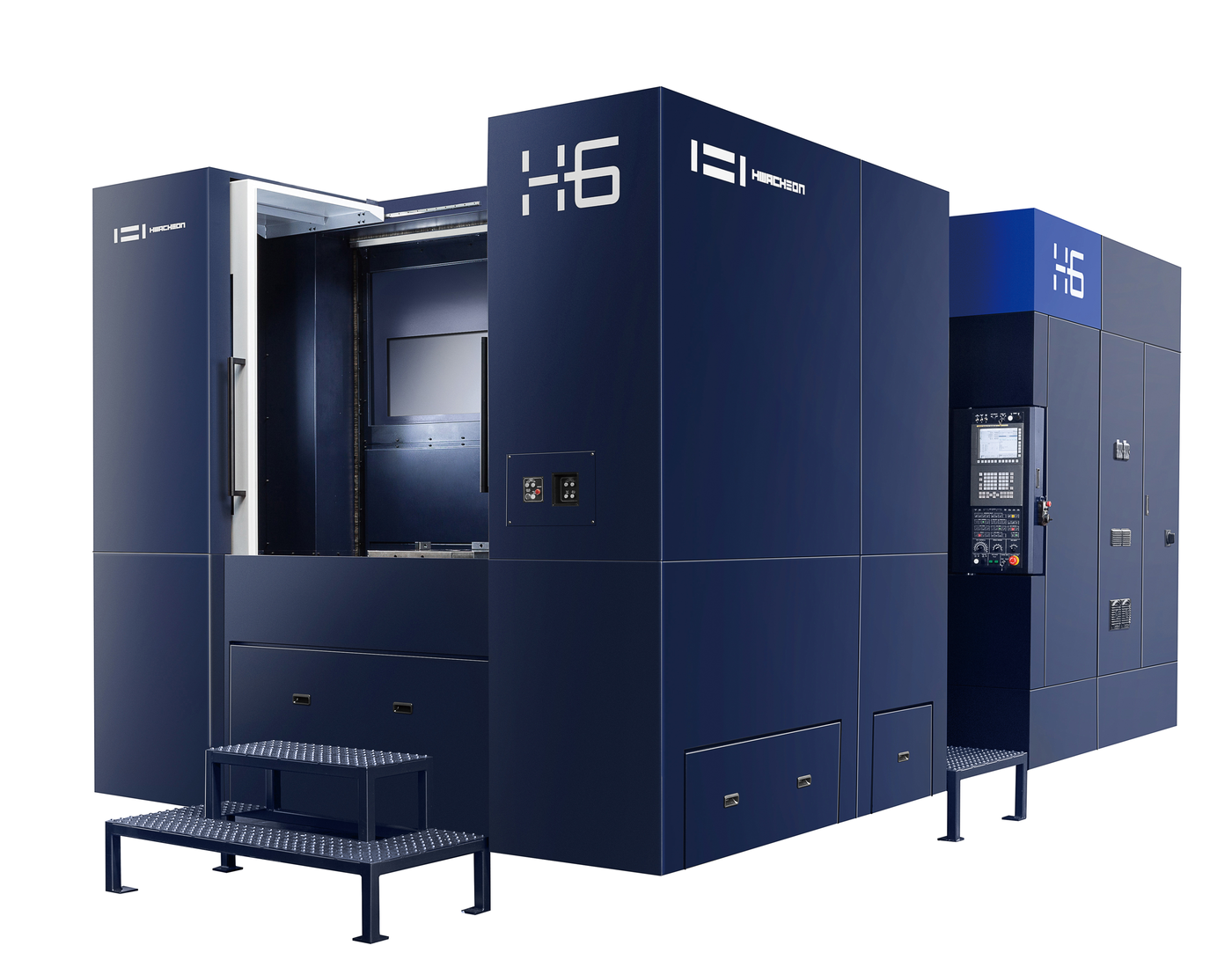

Precision and Power – The H Series by Hwacheon

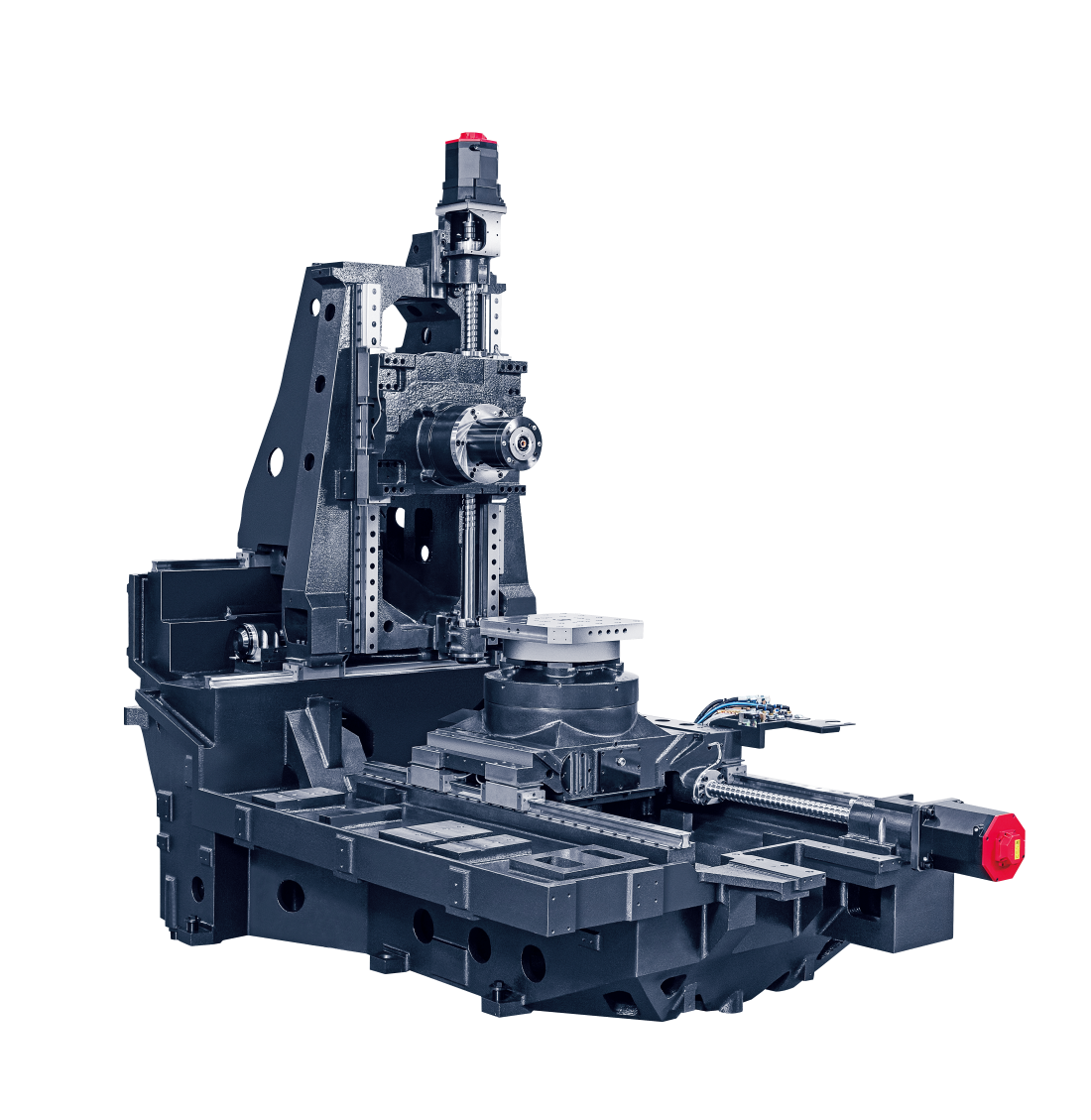

The H series is characterized by its massive machine beds, wide flat guides, and powerful twin drives. It is ideal for tough, hard materials with high chip removal volumes and precision requirements.

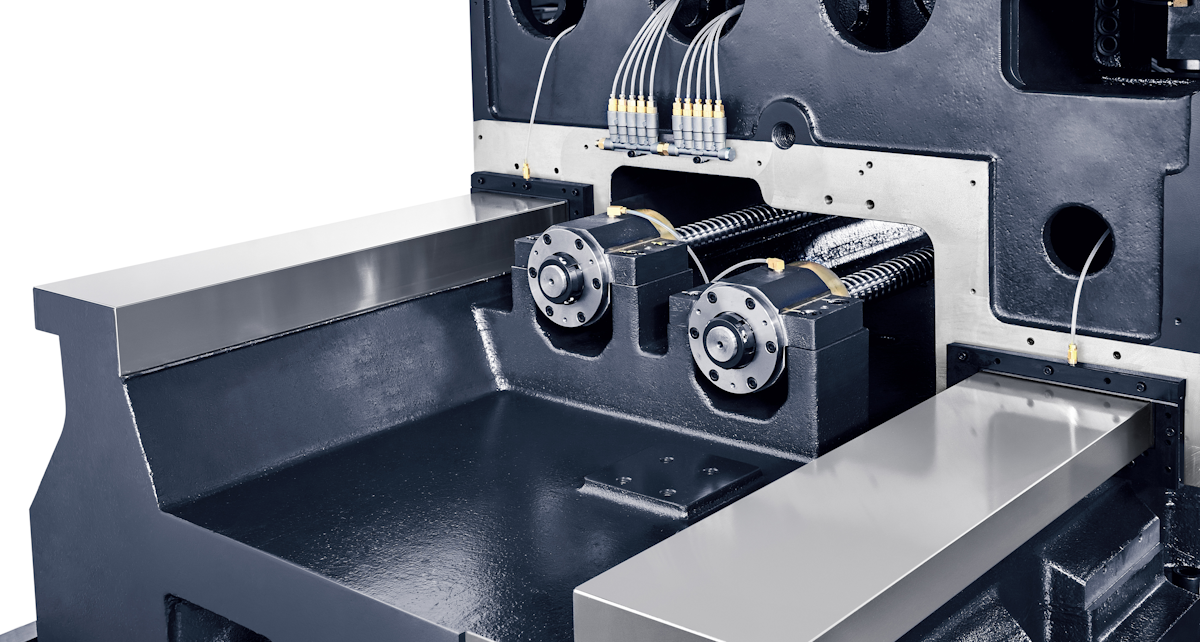

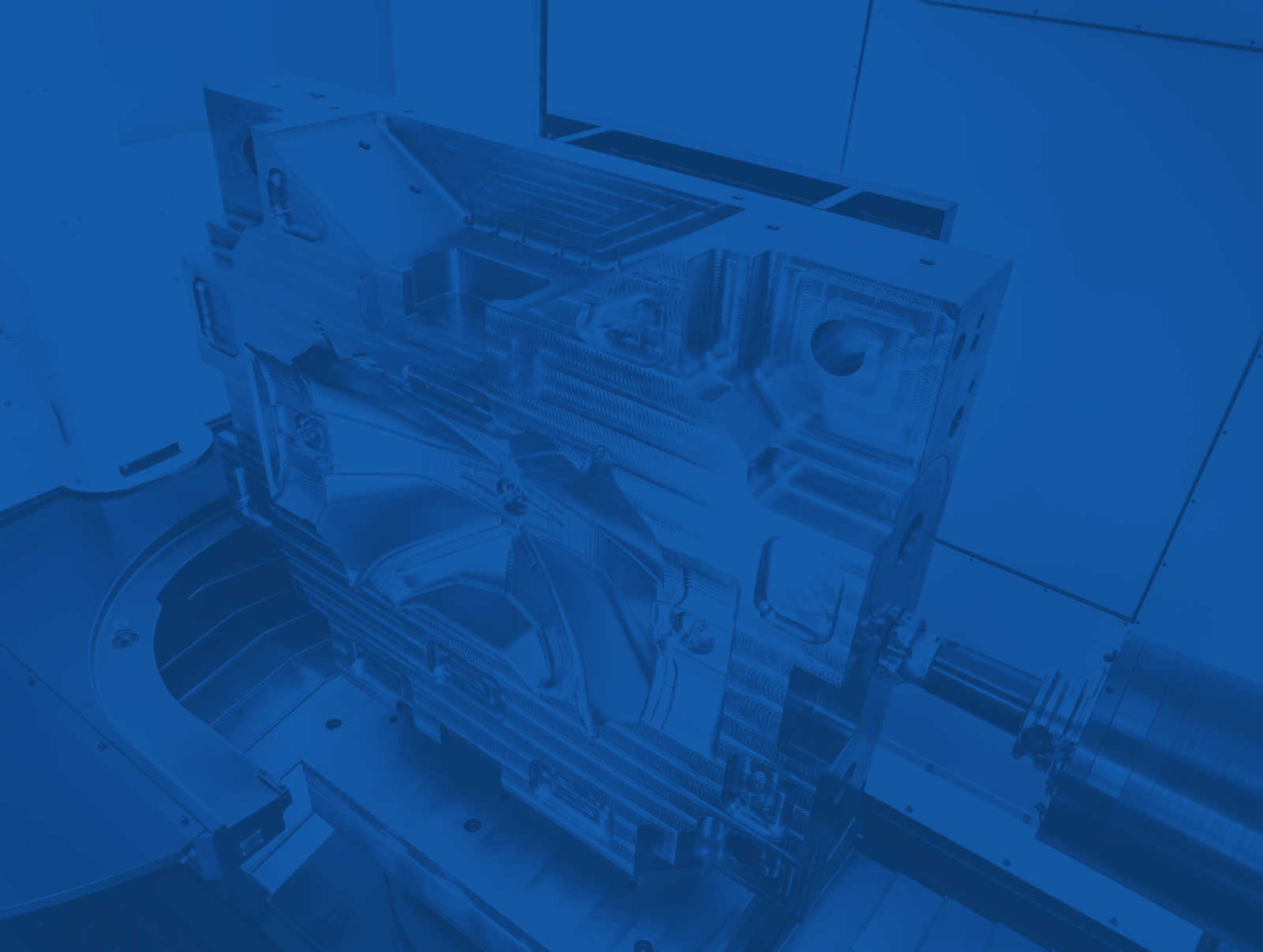

The perfect symbiosis of stability, performance, and precision! The extremely robust H6 and H8 impress with generously sized flat guides in all axes, twin drives in the X and Y axes, and their high-torque BBT-50 spindles (optional HSK-A100).

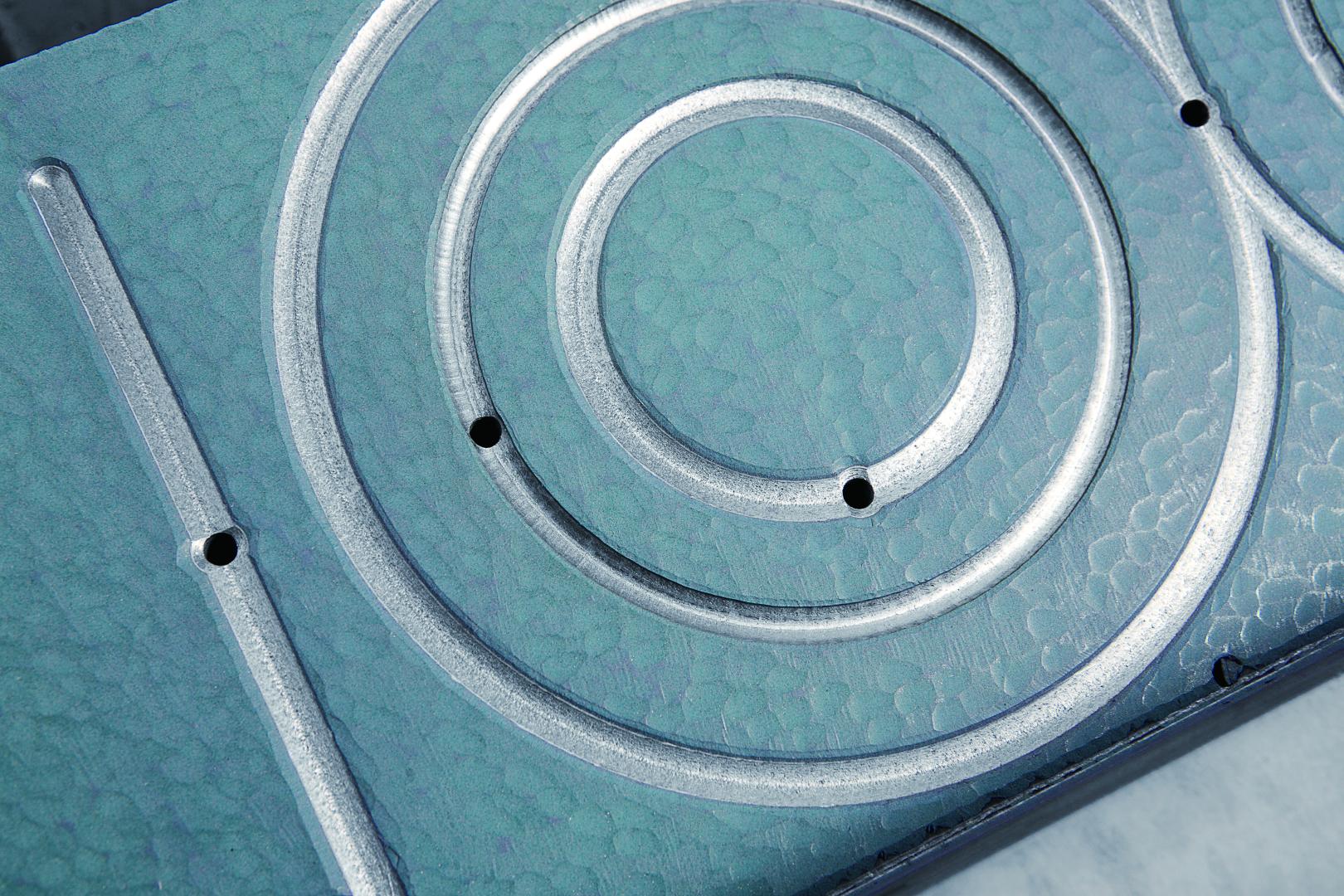

The generously sized flat guides and the twin drives in the X and Y axes allow for precise and high chip removal rates. The air-pressurized flat guides have low breakaway torque and ensure uniform movements. The high drive torque of the geared spindle and the unique Hwacheon oil-jet cooling system provide stable high-performance machining and the highest processing quality, even during longer machining times.

Available Spindles (BBT-50 / HSK-A100)

- 8,000 rpm (35/22 kW and 1654 Nm), 2-stage gearbox

- 12,000 rpm (30/25 kW and 420 Nm), motor spindle

Perfect for Tough Materials

With the horizontal machining centers H6 and H8, Hwacheon offers the ideal solution for the highest machining requirements. Designed for stability and precision, these machines are the perfect choice for powerful roughing and dynamic finishing.

When it comes to machining challenging materials, interrupted cuts, and high chip removal rates, the H-series is your ultimate solution. Renowned for its precision and exceptional surface quality, the H-series stands out for its performance and reliability.

- Twin drives in the X and Y axes

- Play-free preloaded ball screw spindles

- Extremely wide flat guides

- Temperature monitoring for machine bed and spindle

- Oil-cooled geared or motor spindle

- Play-free preloaded precision drive in the B-axis

- Massive T-shaped machine bed made of vibration-damping Meehanite cast iron

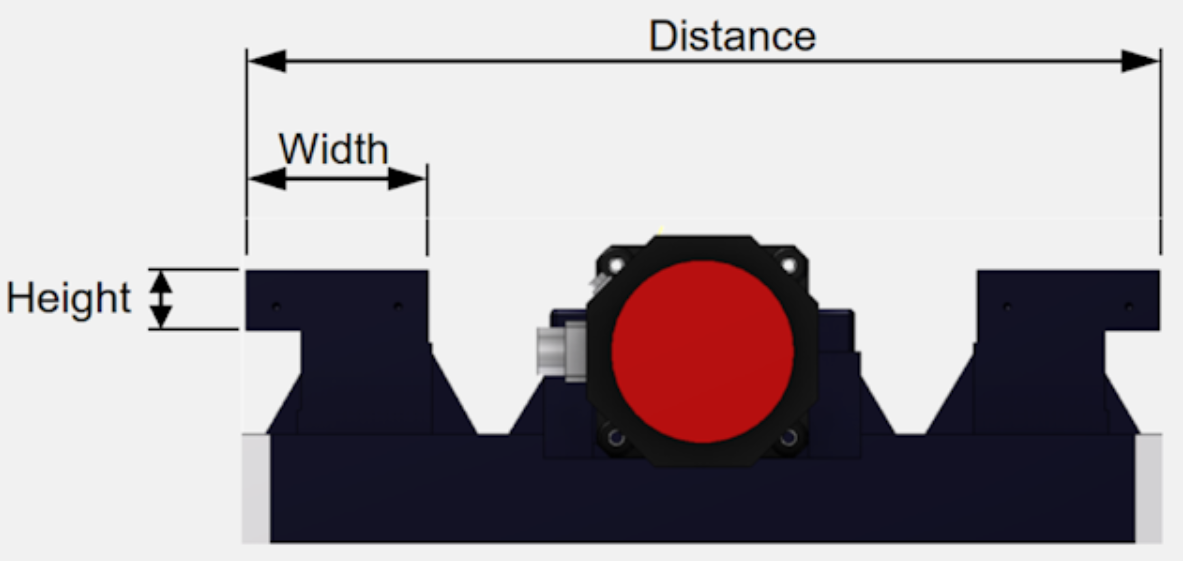

BOX GUIDE WAYS | DRIVES | Ballscrew Dia. | |||

|---|---|---|---|---|---|

Height | Width | Distance | Power | ||

| X axis | 50 mm | 170 mm | 1000 mm | 2 x 6 kW | Ø 45 mm |

| Y axis | 60 mm | 162 mm | 764 mm | 2 x 7 kW | Ø 40 mm |

| Z axis | 50 mm | 150 mm | 750 mm | 1 x 9 kW | Ø 50 mm |