Vertical Turning Centers

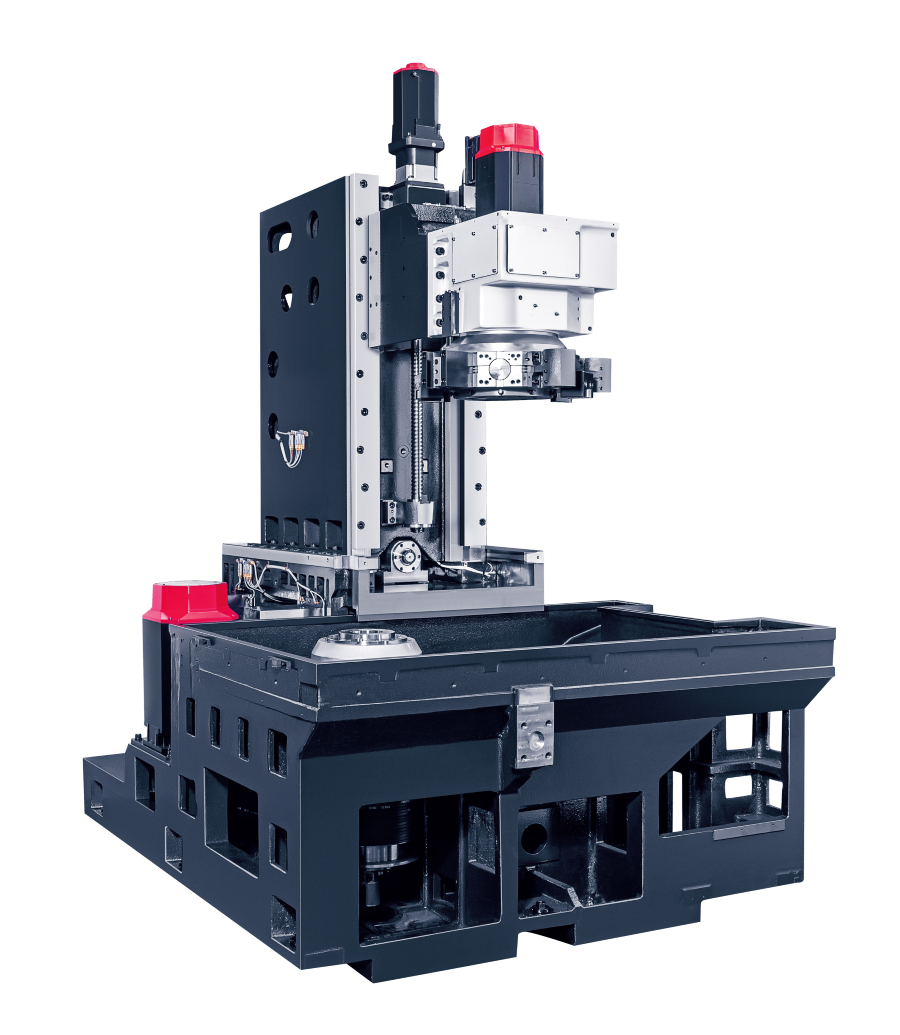

Vertical Turning Centers (Linear Roller Guides)

Where Precision and Performance Merge

Precision, efficiency, and flexibility – the vertical lathes VT-450 and VT-650 from Hwacheon are the ideal solution for medium to high volume production.

Whether machining steel, non-ferrous metals, or plastics: these turning centers impress with their productivity even under the most demanding cutting conditions.

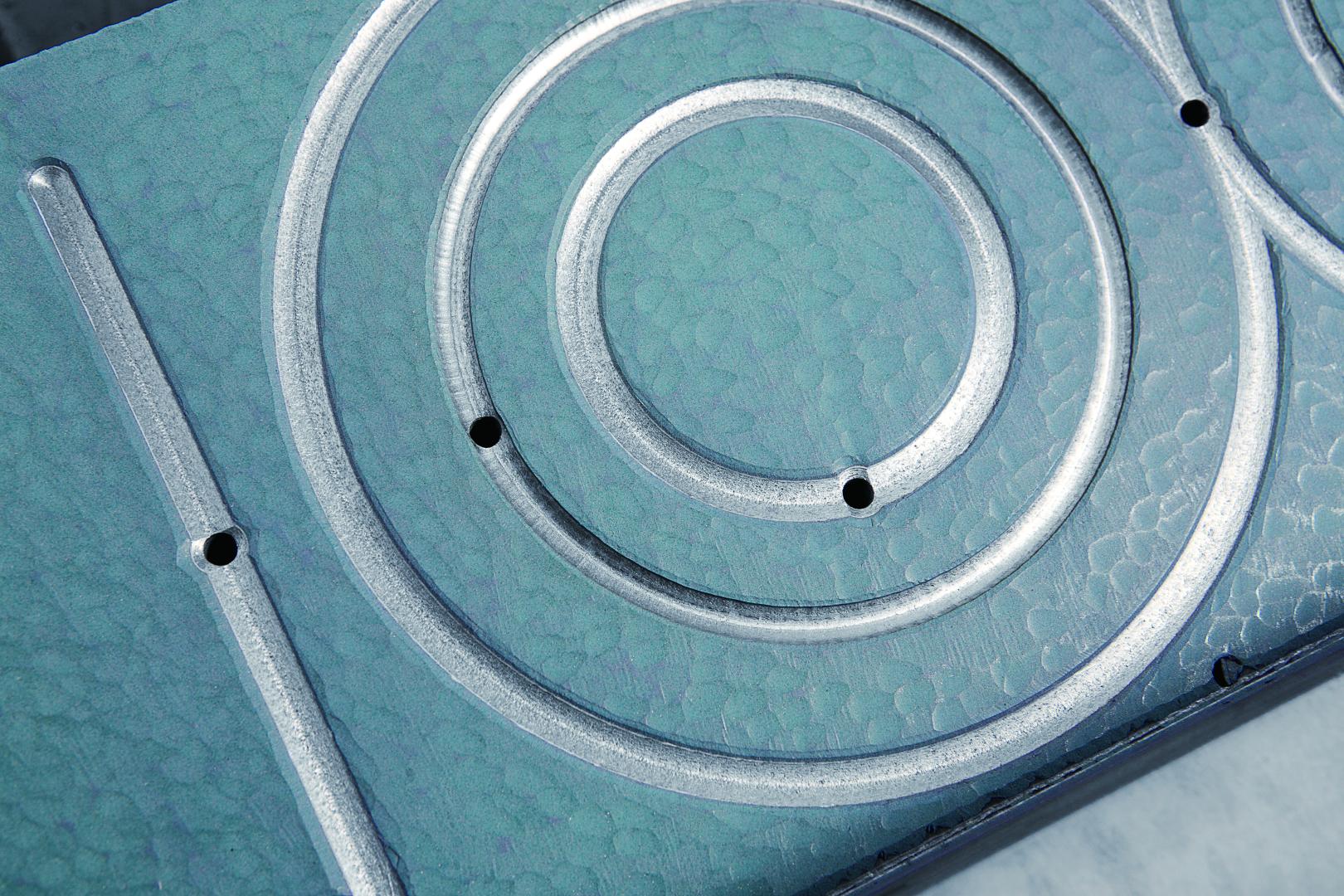

The vertical lathes VT-450 and VT-650 set new standards in the machining of round and disc-shaped workpieces. The vertical design simplifies clamping, optimizes chip flow, and saves space. Their massive Meehanite cast construction ensures optimal vibration damping and minimizes thermal expansion, guaranteeing consistently high precision and surface quality even during continuous operation.

Powerful, Precise, and Space-Saving

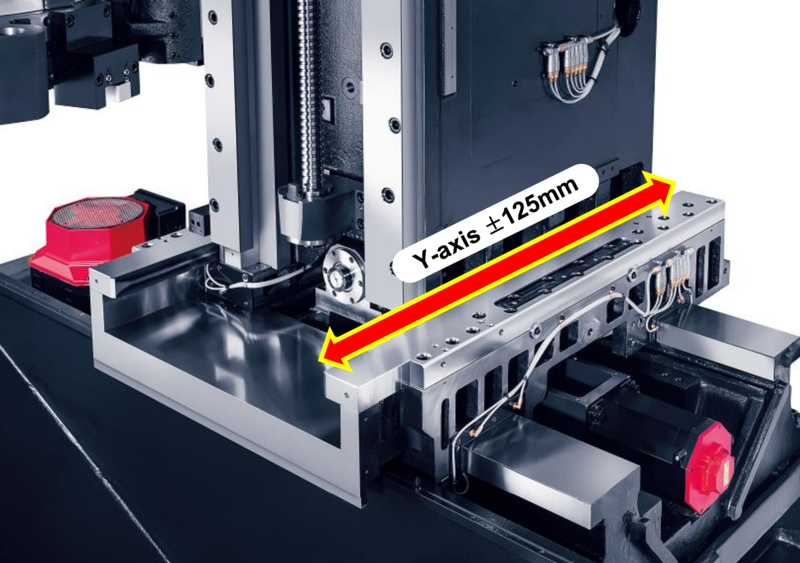

The machines offer maximum flexibility: whether with driven tool stations, an additional tool magazine, or the Y-axis on the VT-650 – these turning centers adapt to your requirements. Powerful spindles and well-designed guide systems ensure efficient machining even of the most demanding workpieces such as brake discs, hubs, or valve housings.

- Flexible configuration: Selectable spindle sides (left/right) for easy automation

- High-precision guide systems: Linear roller guides (VT-450) and box guideways (VT-650, Z-axis)

- Powerful spindles: Up to 45 kW with optional gear-driven spindles

- Tool magazine with Capto interface: For automatic and uninterrupted production

- Y-axes: Optional 250 mm travel in Y on the VT-650 for additional machining capabilities

Vertical Turning Centers (Box Guideways)

Perfect Combination of Power and Precision with Box Guideways

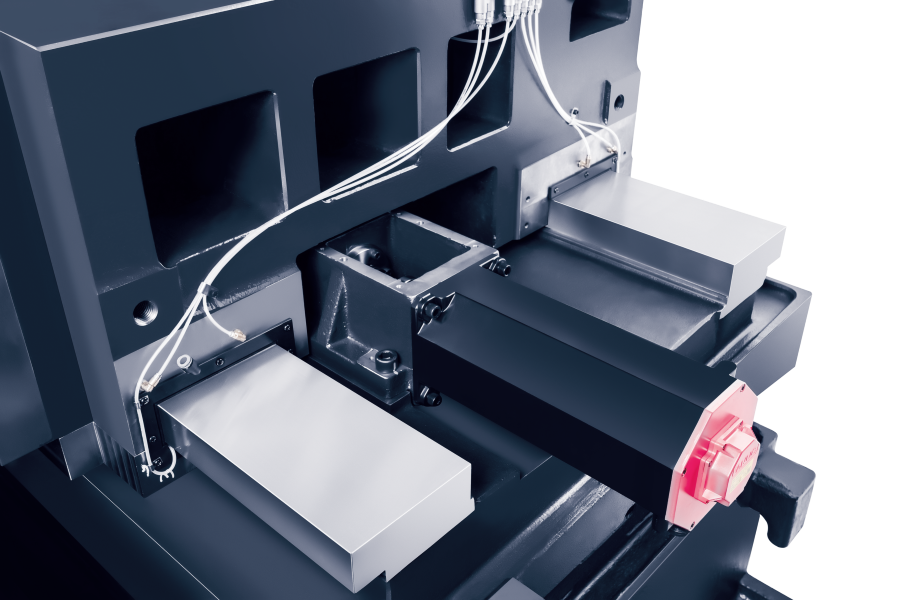

The vertical turning centers VT-950+ and VT-1150+ from Hwacheon combine unmatched stability and exceptional performance. Thanks to their massive construction and advanced technologies, these machines are the ideal choice for the most demanding machining tasks.

Maximale Stabilität für höchste Präzision

Die VT-950+ und VT-1150+ basieren auf einem massiven Meehanite-Gussbett, das mit seiner robusten Bauweise unerwünschte Schwingungen effektiv absorbiert. Das außergewöhnlich hohe Maschinengewicht von 15 bzw. 25 Tonnen garantiert eine unerreichte Vibrationsdämpfung und macht diese Modelle zu den Schwergewichten ihrer Klasse. Breite Flachführungen und ein robuster Fahrständer sorgen für präzise Bearbeitung selbst bei herausfordernden Werkstoffen und hohen Belastungen.

Powerful Performance and Modern Technologies

With high-torque spindles, a 2-stage spindle gearbox, and dynamic feed drives, the VT-950+ and VT-1150+ effortlessly handle even the heaviest machining tasks. The air-floating technology ensures exceptional dynamics: by reducing breakaway torque and the stick-slip effect, impressive machining results can be achieved even at rapid traverse speeds of 24 m/min. Complemented by optional tool magazines and driven tools, these machines offer maximum flexibility for a wide range of applications.

- Massives Meehanite-Gussbett für exzellente Vibrationsdämpfung

- 2-stufiges Spindelgetriebe und High-Torque-Spindeln für maximale Leistung

- Air-Floating-Technologie für hohe Dynamik und Präzision

- Werkzeugmagazin mit Capto-Schnittstelle für automatische Werkzeugwechsel

- Steuerungsoptionen: Fanuc oder Siemens für intuitive Bedienung und Programmierung

Large Vertical Lathe: VT-2000