Over 80 years of detailed experience: Hwacheon combines traditional craftsmanship with modern technology. Our expertise in machine tool manufacturing ensures high production quality and continuous innovation for future-proof concepts in the German market.

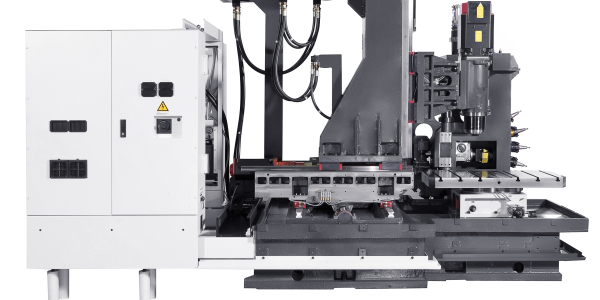

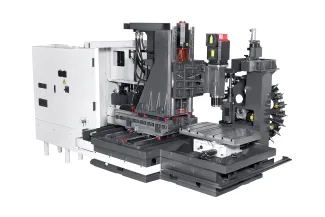

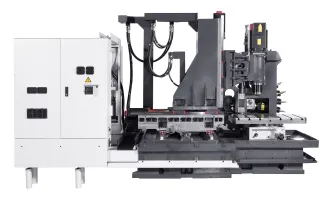

VESTA-610D

Category

Universal Milling MachinesMachine series

VESTA - BaureiheAvailable with

- Siemens 828D

- Fanuc 0i Plus

- Heidenhain iTNC 620

Size of VESTA-610D

- Axis-Stroke (X / Y / Z)610 / 430 / 570mm

- Table size(2x) 650 x 450mm

- Tool shankBBT-40

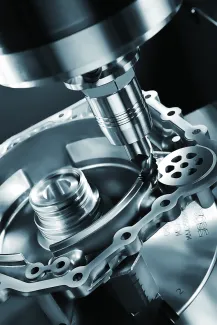

Tradition Meets Modernity

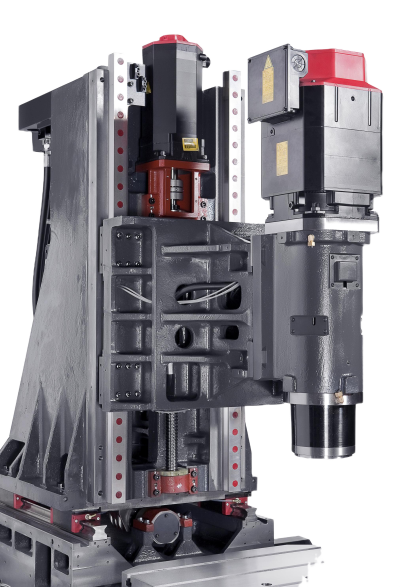

Dynamic Linear Guides

Speed and Dynamics Combined: Linear roller guides provide high dynamics and rapid traverse speeds. The workpiece weight is transferred linearly to the rollers, which must withstand enormous pressure at contact points. Therefore, we exclusively use linear roller guides from renowned manufacturers.

Why choose us?

Pure Precision

Quality that shapes: Our machining centers and lathes offer precision that directly contributes to your success. With 80 years of experience in machine building, you get products specifically designed to meet the demands of complex production processes.

In-House Quality

Quality is created here: With our own manufacturing depth, including foundry and spindle production, we ensure durable and reliable machines. Quality and control go hand in hand to meet the German standards.

Technical Data

| Item | Unit | VESTA-610D |

|---|---|---|

| Axis-Stroke (X / Y / Z) | mm | 610 / 430 / 570 |

| Table size | mm | (2x) 650 x 450 |

| Table load | kg | 300 |

| Spindle power | kW | 15 / 11 |

| Spindle speed | rpm | 10000 |

| Spindle torque | Nm | 95.5 / 70 |

| Feedrate | mm/min | 24000 |

| Rapid speed | m/min | 40 / 40 / 40 |

| Tool shank | BBT-40 | |

| Number of tools | m/min | 24 |

| Machine weight | kg | 7500 |

| Coolant tank vol. | Liter | 395 |

Features of VESTA-610D

Double Swivel Table

Main-Time Parallel Loading and Unloading: The double swivel table allows loading and unloading of one table half during main time while the other side is machined in the workspace. This feature saves valuable time and is ideal for automating such machine types. It enables optimal timing of production processes in linked machines, eliminating unproductive waiting times for the previous process.

| Table size | mm | (2x) 650 x 450 |

| Table load | kg | 300 |

Peripherals and accessories

Dynamic Linear Guides

Speed and Dynamics Combined: Linear roller guides provide high dynamics and rapid traverse speeds. The workpiece weight is transferred linearly to the rollers, which must withstand enormous pressure at contact points. Therefore, we exclusively use linear roller guides from renowned manufacturers.

Internal Coolant Supply

ICS Makes the Difference!: The internal coolant supply (ICS) delivers coolant directly to the cutting edge, optimizing lubrication and chip removal. It boosts productivity, extends tool life, and enhances process reliability.

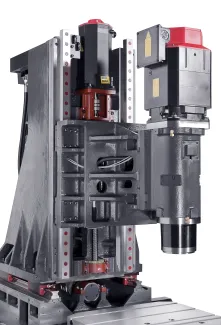

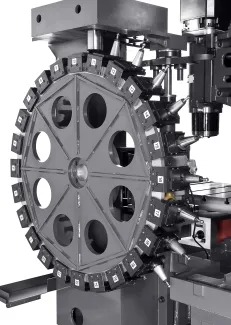

Automatic Tool Changer

| Tool shank | BBT-40 | |

| Number of tools | m/min | 24 |

High-Quality Spindle

Consistent Cooling and Lubrication for Maximum Precision: Our in-house manufactured spindles are cooled and lubricated by an innovative air-oil aerosol system, while temperature sensors ensure constant monitoring. This advanced technology guarantees exceptional durability and outstanding smoothness. Experience maximum precision with minimal thermal growth for consistent performance even under the most demanding conditions.

High-Quality Pretensioned Ball Screws

Thermal Stability for Precision and Reliability: Pretensioned ball screws reliably and stably compensate for thermal expansion. This technology prevents unwanted elongation of the spindles, ensuring lasting precision and consistently high machining accuracy over extended operating periods.

Excellent Chip Disposal

Perfect Chip Removal for Your Machine!: Our innovative chip disposal systems reliably remove chips, reduce heat, and optimize machining. High-quality components ensure uninterrupted operation and maximum process reliability.

- Coolant tank vol.395Liter

Other features and options

Spindle (general), BBT-40 / BT-40, Siemens 828D, Fanuc 0i Plus, Heidenhain iTNC 620, Chip Conveyor, Work table, Workspace, Tool measuring, Machine SizeVESTA-660

- Axis-Stroke (X / Y / Z)660 / 430 / 400mm

- Table size720 x 420mm

- Tool shankBBT-40

VESTA-1000+

- Axis-Stroke (X / Y / Z)1.000 / 550 / 500mm

- Table size1.100 x 502mm

- Tool shankBBT-40 / BT-40No unit

VESTA-1300+

- Axis-Stroke (X / Y / Z)1330 / 670 / 650mm

- Table size1500 x 670

- Tool shankBBT-40 / 50

VESTA-1650

- Axis-Stroke (X / Y / Z)1650 / 750 / 675mm

- Table size1700 x 750mm

- Tool shankBBT-40 / 50No unit

Pagination

- Page 1

- Next page

-->

-->