Over 80 years of detailed experience: Hwacheon combines traditional craftsmanship with modern technology. Our expertise in machine tool manufacturing ensures high production quality and continuous innovation for future-proof concepts in the German market.

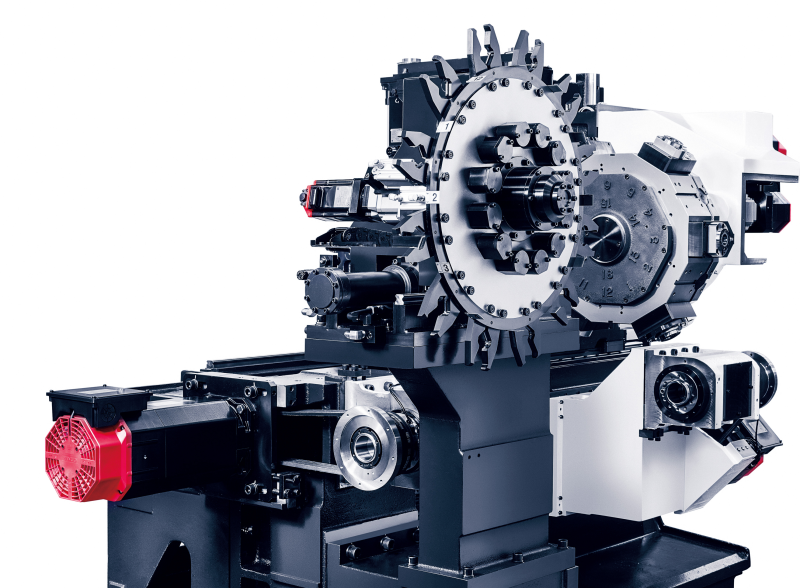

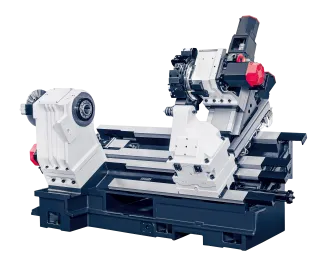

Hi-TECH 230

Category

Heavy-Duty Cutting LathesMachine series

Hi-TECH - BaureiheAvailable with

- Siemens 828D

- Fanuc 0i Plus

Size of Hi-TECH 230

| Max. cutting diameter | mm | 400 - 425 | ||||||||

| Chuck-Size | mm | 200 - 250 | ||||||||

| Swing over bed | mm | 690 | ||||||||

Tradition Meets Modernity

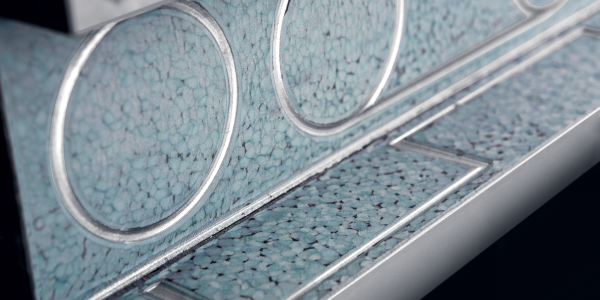

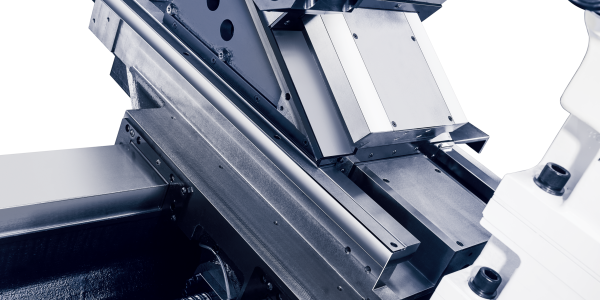

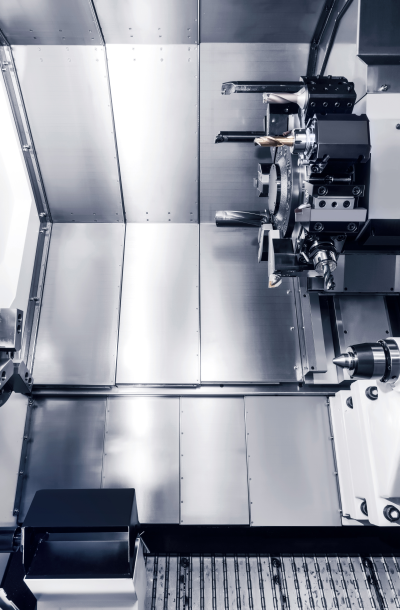

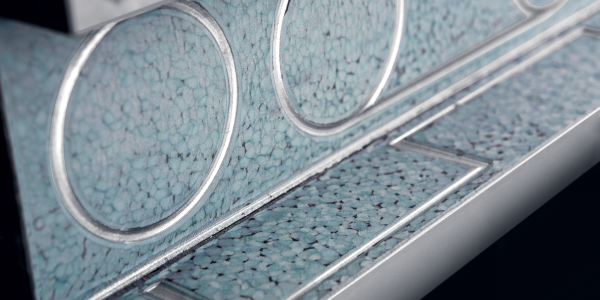

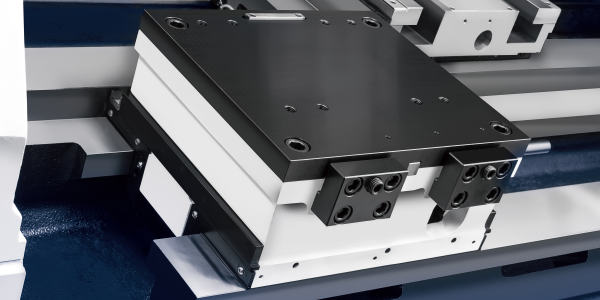

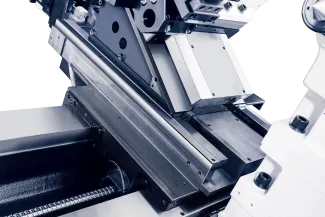

Flat Guides

Excellent Damping Properties: Box or flat guides effectively absorb vibrations from the machining process by transferring them into the machine bed due to their large contact surface. Hand-fitted and scraped by experienced staff, these guides ensure precision. Central oil lubrication provides continuous lubrication with bedway oil, while the Turcite coating on the sliding surface offers excellent emergency running properties. Machines with flat guides are more durable and can handle higher chip volumes. Thanks to these unique features, they are considered particularly powerful and reliable.

Why choose us?

Satisfaction Guaranteed

Partnership that counts: Long-term customer relationships are characterized by transparency and continuous feedback. Our commitment to quality and service ensures an attractive price-performance ratio for our German customers.

Future-Proof Solutions

Innovation in every machine: State-of-the-art technologies shape our machine concepts, based on the latest standards for turning and milling machines. You benefit from efficient solutions, customized to your requirements.

Pure Precision

Quality that shapes: Our machining centers and lathes offer precision that directly contributes to your success. With 80 years of experience in machine building, you get products specifically designed to meet the demands of complex production processes.

Technical Data

| Item | Unit | Hi-TECH 230A | Hi-TECH 230AL | Hi-TECH 230AXL | Hi-TECH 230B | Hi-TECH 230BL | Hi-TECH 230BXL | Hi-TECH 230C | Hi-TECH 230CL | Hi-TECH 230CXL |

|---|---|---|---|---|---|---|---|---|---|---|

| Axis-Stroke (X / Y / Z) | mm | 240 / 120 / 460 | 240 / 120 / 700 | 240 / 120 / 1200 | 240 / 120 / 460 | 240 / 120 / 700 | 240 / 120 / 1200 | 240 / 120 / 460 | 240 / 120 / 700 | 240 / 120 / 1200 |

| Spindle power | kW | 18.5 / 15 | 22 / 18.5 | |||||||

| Spindle speed | rpm | 4500 | 3500 | |||||||

| Spindle torque | Nm | 330 / 200 | 330 / 200 | 410 / 250 | 704 / 416 | 703.5 / 416 | ||||

| Rapid speed | m/min | 30 / 10 / 30 | ||||||||

| Tool shank | BMT-65 / BH | |||||||||

| Number of tools | 12 | |||||||||

| Machine weight | kg | 5800 | 6650 | 8200 | 6800 | 6650 | 8200 | 6050 | 6750 | 8300 |

| Max. cutting diameter | mm | 425 | 400 | 425 | 400 | |||||

| Max. cutting length | mm | 403 | 584 | 1143 / 1084 | 379 | 560 | 1119 / 1060 | 379 | 560 | 1119 / 1060 |

| Chuck-Size | mm | 200 | 250 | |||||||

| Swing over bed | mm | 690 | ||||||||

| Max. Bar size | mm | 65 | 81 | |||||||

| Coolant tank vol. | Liter | 160 | 150 | 160 | 125 | 160 | 125 | 150 | ||

Configurations

| Y | MC | S | |

|---|---|---|---|

| Hi-TECH 230A | Optional | Optional | |

| Hi-TECH 230A(X)L | Optional | Optional | Optional |

| Hi-TECH 230B | Optional | Optional | |

| Hi-TECH 230B(X)L | Optional | Optional | Optional |

| Hi-TECH 230C | Optional | Optional | |

| Hi-TECH 230C(X)L | Optional | Optional | Optional |

Features of Hi-TECH 230

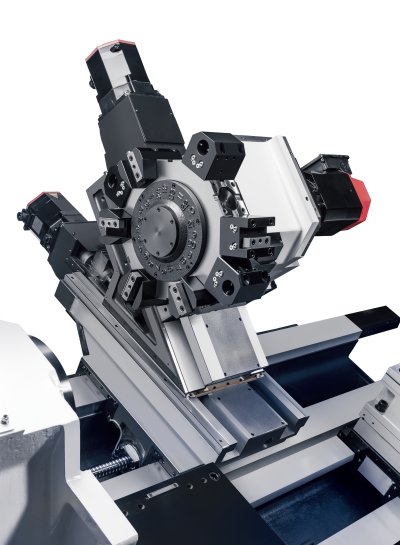

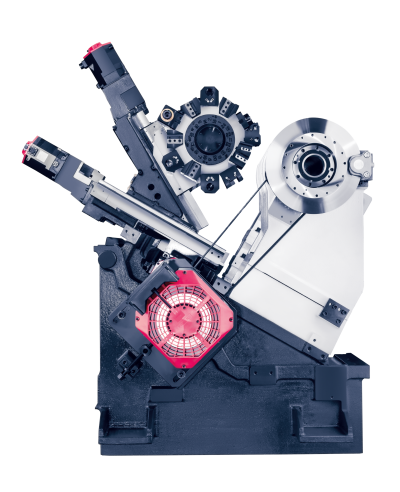

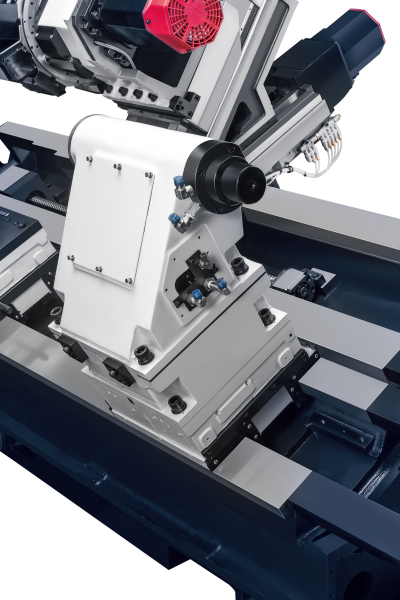

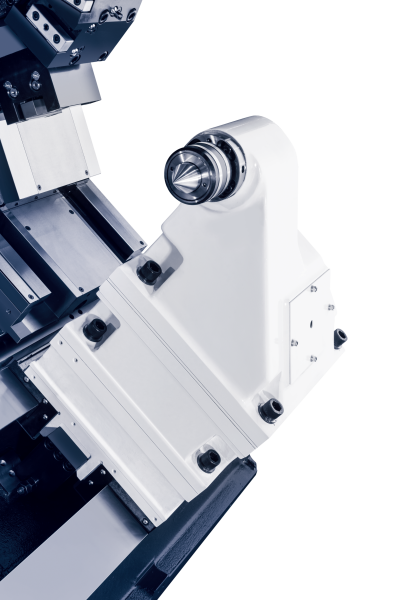

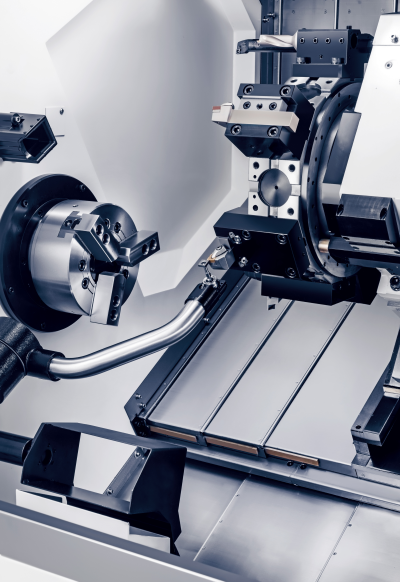

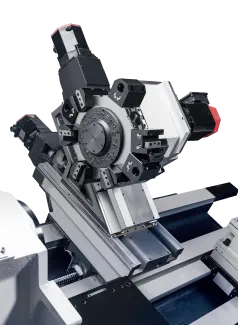

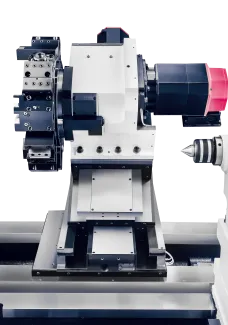

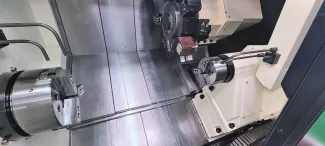

Y-Axis

Greater Flexibility and Time Savings: Lathes with a Y-axis enable 3-axis interpolation movements and the creation of off-center bores and milling operations. This allows workpieces to be fully machined in a single setup, eliminating operations on other machines and increasing machining accuracy. Additionally, they optimize grooving and parting processes by reducing lever forces for faster workflows.

| Item | Unit | Hi-TECH 230A | Hi-TECH 230AL | Hi-TECH 230AXL | Hi-TECH 230B | Hi-TECH 230BL | Hi-TECH 230BXL | Hi-TECH 230C | Hi-TECH 230CL | Hi-TECH 230CXL |

|---|---|---|---|---|---|---|---|---|---|---|

| Axis-Stroke (X / Y / Z) | mm | 240 / 120 / 460 | 240 / 120 / 700 | 240 / 120 / 1200 | 240 / 120 / 460 | 240 / 120 / 700 | 240 / 120 / 1200 | 240 / 120 / 460 | 240 / 120 / 700 | 240 / 120 / 1200 |

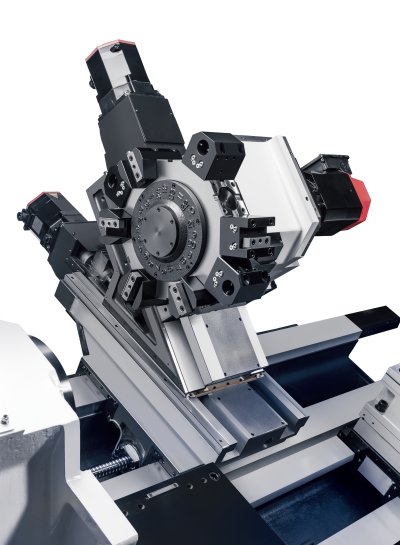

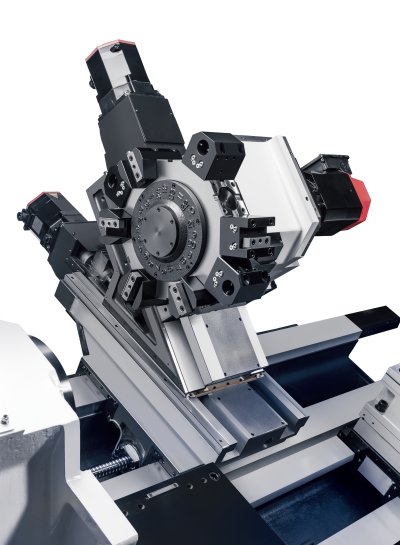

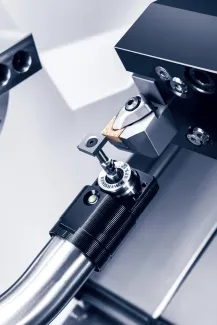

Turret

| Tool shank | BMT-65 / BH | |||||||||

| Number of tools | 12 | |||||||||

Tailstock

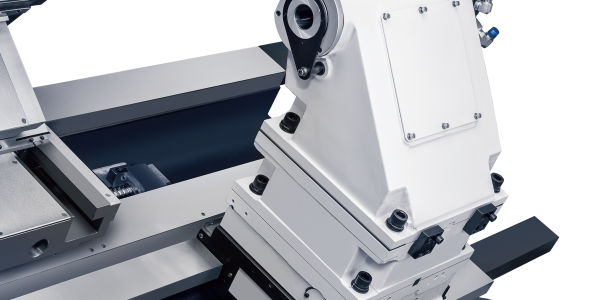

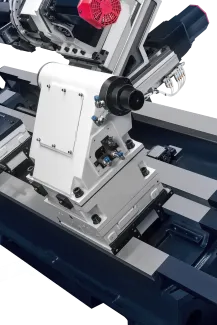

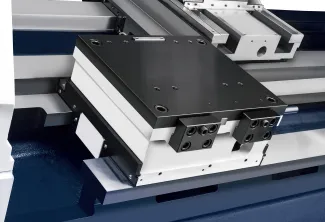

Flat Guides

Excellent Damping Properties: Box or flat guides effectively absorb vibrations from the machining process by transferring them into the machine bed due to their large contact surface. Hand-fitted and scraped by experienced staff, these guides ensure precision. Central oil lubrication provides continuous lubrication with bedway oil, while the Turcite coating on the sliding surface offers excellent emergency running properties. Machines with flat guides are more durable and can handle higher chip volumes. Thanks to these unique features, they are considered particularly powerful and reliable.

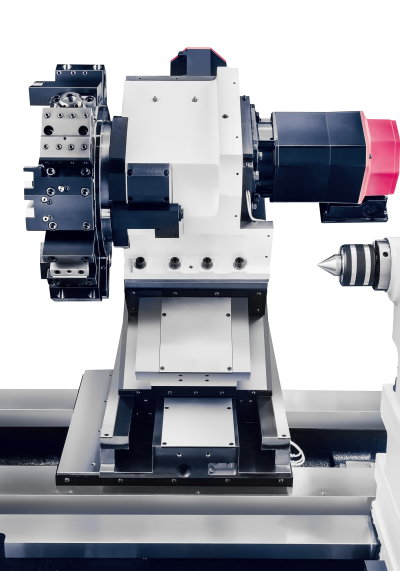

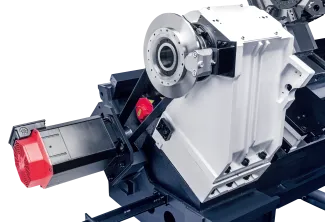

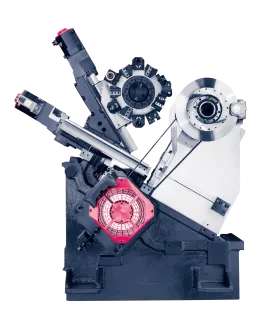

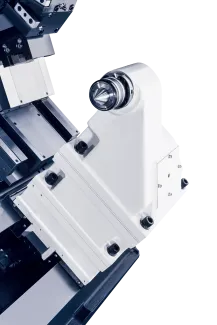

Counter Spindle

Precision in Every Dimension: Lathes with a counter spindle enable back-side machining of workpieces and can alternatively be used as an NC tailstock. This back-side machining saves time and effort by eliminating the need for re-clamping on another machine. It also improves precision since the workpiece does not need realignment. For enhanced process stability and safe ejection of finished workpieces, optional pneumatic or mechanical ejectors and spindle flushing can be added.

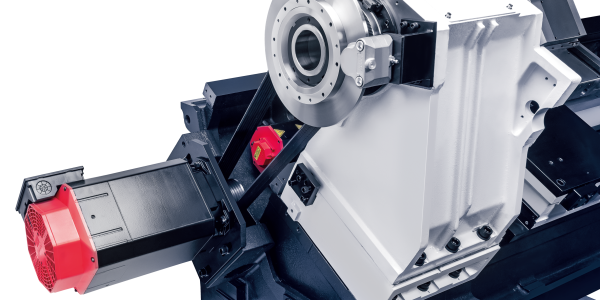

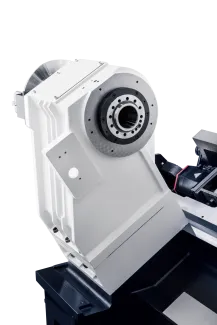

Belt-Driven Spindle

| Item | Unit | Hi-TECH 230A | Hi-TECH 230AL | Hi-TECH 230AXL | Hi-TECH 230B | Hi-TECH 230BL | Hi-TECH 230BXL | Hi-TECH 230C | Hi-TECH 230CL | Hi-TECH 230CXL |

|---|---|---|---|---|---|---|---|---|---|---|

| Spindle power | kW | 18.5 / 15 | 18.5 / 15 | 18.5 / 15 | 18.5 / 15 | 18.5 / 15 | 18.5 / 15 | 22 / 18.5 | 22 / 18.5 | 22 / 18.5 |

| Spindle speed | rpm | 3500 - 4500 | ||||||||

| Spindle torque | Nm | 330 / 200 | 330 / 200 | 330 / 200 | 410 / 250 | 410 / 250 | 410 / 250 | 704 / 416 | 703.5 / 416 | 703.5 / 416 |

| Max. Bar size | mm | 65 - 81 | ||||||||

Parts catcher

Steady Rest Carriage

Stability for Precise Results: The steady rest ensures maximum precision for long workpieces through optimal support. It reduces vibrations, improves surface quality, and enables precise machining even for demanding projects.

Clamping Technology

| Chuck-Size | mm | 200 - 250 | ||||||||

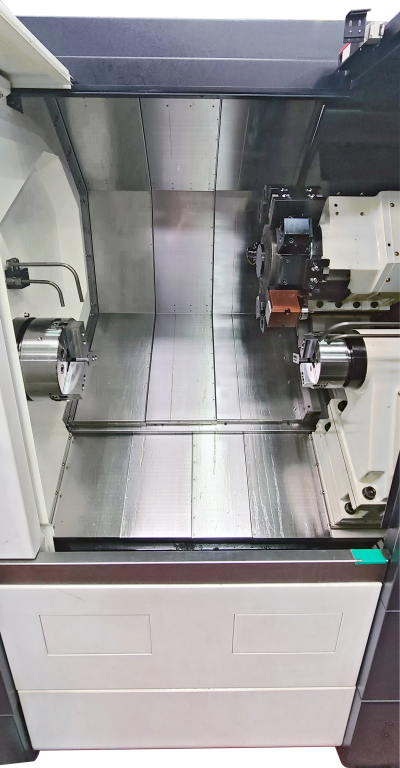

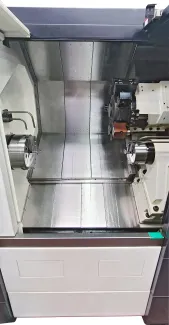

Workspace

Tool measuring

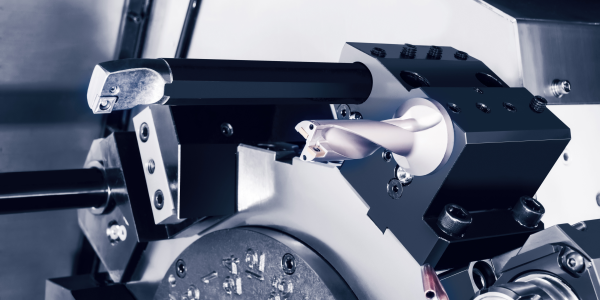

Driven Tools

Precision and Versatility Combined: Driven tools on lathes significantly expand machining capabilities. They enable milling, drilling, and other processes directly on the lathe, reducing re-clamping operations and minimizing downtime. Using various tools in a single setup increases machining accuracy and boosts overall productivity.

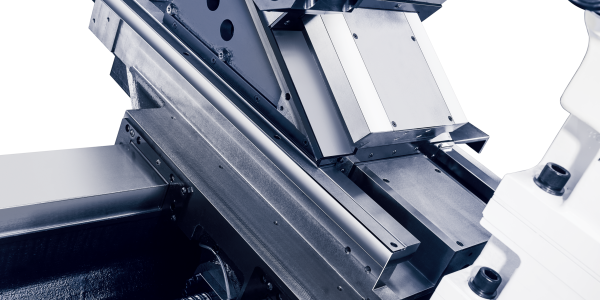

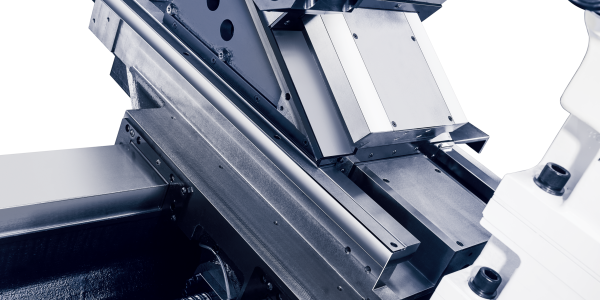

High-Quality Pretensioned Ball Screws

Thermal Stability for Precision and Reliability: Pretensioned ball screws reliably and stably compensate for thermal expansion. This technology prevents unwanted elongation of the spindles, ensuring lasting precision and consistently high machining accuracy over extended operating periods.

Excellent Chip Disposal

Perfect Chip Removal for Your Machine!: Our innovative chip disposal systems reliably remove chips, reduce heat, and optimize machining. High-quality components ensure uninterrupted operation and maximum process reliability.

- Coolant tank vol.160Liter

- Coolant tank vol.150Liter

- Coolant tank vol.125Liter

-->

-->