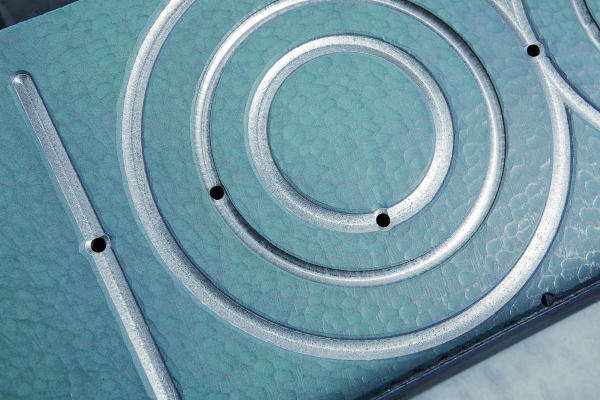

In comparison with linear guideways with rollers, box guideways have a significantly larger bearing face between the two mounted carriages and the machine bed. This means that the vibrations which are generated during the cutting process at the cutting edge are more effectively transmitted into the machine bed which, due to its high mass and damping characteristics, is extremely effective at absorbing them. This extends the life of tools, and helps them run more smoothly, resulting in better-quality surfaces on the workpiece and better cutting performance. The greater surface area also means that significantly heavier workpieces can be mounted and moved.

Additional advantages of box guideways are their extreme durability and low sensitivity to collisions (“crash situations”).

Hwacheon's air floating system

In order to minimise the break loose torque and the stick-slip effect, the gap in the box guideways is charged with compressed air. This ensures the optimal distribution of the guideway oil and particularly smooth movement over small distances and during oscillatory movements.

Box guideways are used in the following series / machines:

- Hi-TECH - Lathes

- VESTA B - Machining centres

- SIRIUS - 850 / 1050 / 1350

- H6 / H8 - Horizontal machining centres

- MEGA - Flat bed lathes

- VT - Vertical lathes

- TTC 10 - Twin spindle lathe (front)

Hwacheon is one of just a few machine tool manufactures world-wide which produces hand-scraped Turcite-coated box guideways.

SIRIUS-850

- Axis-Stroke (X / Y / Z)2000 / 850 / 750mm

- Table size2150 x 850mm

- Tool shankBBT-50

SIRIUS-1350

- Axis-Stroke (X / Y / Z)2550 / 1350 / 750mm

- Table size2800 x 1250mm

- Tool shankBBT-50

VESTA-850B

- Axis-Stroke (X / Y / Z)850 / 600 / 600mm

- Table size1050 x 600mm

- Tool shankBT-40

VESTA-1050B

- Axis-Stroke (X / Y / Z)1050 / 600 / 600mm

- Table size1150 x 600mm

- Tool shankBBT-40 / 50

VESTA-1300B+

- Axis-Stroke (X / Y / Z)1330 / 670 / 650mm

- Table size1500 x 670mm

- Tool shankBBT-40 / BBT-50No unit

H6

- Axis-Stroke (X / Y / Z)1050 / 900 / 1000mm

- Pallet size630 x 630mm

- Tool shankBBT-50 (HSK-100)

SIRIUS-1050

- Axis-Stroke (X / Y / Z)2500 / 1050 / 850mm

- Table size2800 x 1050mm

- Tool shankBBT-50

H8

- Axis-Stroke (X / Y / Z)1400 / 1150 / 1250mm

- Pallet size800 x 800 (800 x 1000)mm

- Tool shankBBT-50 (HSK-100)

M4-5AX

- Axis-Stroke (X / Y / Z)950 / 1.000 / 650mm

- Table sizeØ800 x 630mm

- Tool shankBBT-50No unit