Over 80 years of detailed experience: Hwacheon combines traditional craftsmanship with modern technology. Our expertise in machine tool manufacturing ensures high production quality and continuous innovation for future-proof concepts in the German market.

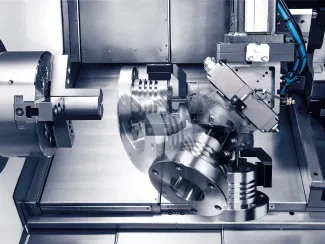

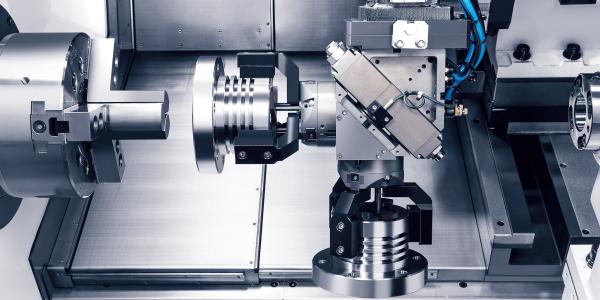

GR - Gantry Loader

Machine series

Automationslösungen von HwacheonAvailable with

- Fanuc 31i

- Fanuc 0i Plus

Size of GR - Gantry Loader

Tradition Meets Modernity

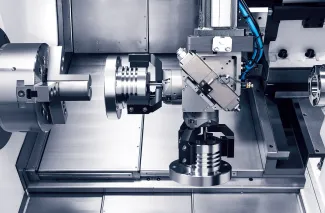

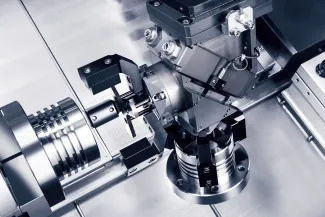

Dynamic Linear Guides

Speed and Dynamics Combined: Linear roller guides provide high dynamics and rapid traverse speeds. The workpiece weight is transferred linearly to the rollers, which must withstand enormous pressure at contact points. Therefore, we exclusively use linear roller guides from renowned manufacturers.

Why choose us?

Tailor-Made

Flexibility is key: With extensive customization options, we design machines that exactly match your application. This gives you precise solutions for maximum efficiency and productivity in your business.

Tradition Meets Modernity

Over 80 years of detailed experience: Hwacheon combines traditional craftsmanship with modern technology. Our expertise in machine tool manufacturing ensures high production quality and continuous innovation for future-proof concepts in the German market.

Pure Precision

Quality that shapes: Our machining centers and lathes offer precision that directly contributes to your success. With 80 years of experience in machine building, you get products specifically designed to meet the demands of complex production processes.

Technical Data

| Item | Unit | GR-10 | GR-5 |

|---|---|---|---|

| Axis-Stroke (X / Y / Z) | mm | 3.020 / 970.5 | |

| Rapid speed | m/min | 150 / 120 / - | |

| Loading + Unloading time | second | 10 | 8 |

| Number of stations (stacker) | Amount | 10 / 14 | |

| Max. Workpiece size (D x L) | mm | 200 x 110 | 155 x 20 |

| Min. Workpiece size (D x L) | mm | 65 x 20 | 48 x 20 |

| Max. stacked height per station | mm | 600 | |

Features of GR - Gantry Loader

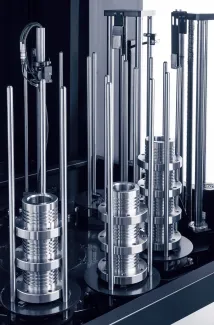

Automatic Workpiece Changer

Autonomy and Efficiency Maximized: Automatic workpiece changers extend a machine’s unmanned operating time by independently changing workpieces without operator intervention. This supports multi-machine operation, optimizes cost-effectiveness, and maximizes machine utilization during extended operating periods.

| Loading + Unloading time | second | 8 - 10 | |

| Number of stations (stacker) | Amount | 10 / 14 | |

| Max. Workpiece size (D x L) | mm | 200 x 110 | 155 x 20 |

| Min. Workpiece size (D x L) | mm | 65 x 20 | 48 x 20 |

| Max. stacked height per station | mm | 600 | |

Dynamic Linear Guides

Speed and Dynamics Combined: Linear roller guides provide high dynamics and rapid traverse speeds. The workpiece weight is transferred linearly to the rollers, which must withstand enormous pressure at contact points. Therefore, we exclusively use linear roller guides from renowned manufacturers.