Over 80 years of detailed experience: Hwacheon combines traditional craftsmanship with modern technology. Our expertise in machine tool manufacturing ensures high production quality and continuous innovation for future-proof concepts in the German market.

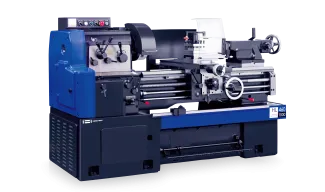

HL (Hwacheon Lathes, conventional)

Category

Conventional LathesMachine series

HL - SeriesAvailable with

Size of HL (Hwacheon Lathes, conventional)

No technical data available.

Tradition Meets Modernity

Flat Guides

Excellent Damping Properties: Box or flat guides effectively absorb vibrations from the machining process by transferring them into the machine bed due to their large contact surface. Hand-fitted and scraped by experienced staff, these guides ensure precision. Central oil lubrication provides continuous lubrication with bedway oil, while the Turcite coating on the sliding surface offers excellent emergency running properties. Machines with flat guides are more durable and can handle higher chip volumes. Thanks to these unique features, they are considered particularly powerful and reliable.

Why choose us?

Tailor-Made

Flexibility is key: With extensive customization options, we design machines that exactly match your application. This gives you precise solutions for maximum efficiency and productivity in your business.

Tradition Meets Modernity

Over 80 years of detailed experience: Hwacheon combines traditional craftsmanship with modern technology. Our expertise in machine tool manufacturing ensures high production quality and continuous innovation for future-proof concepts in the German market.

Pure Precision

Quality that shapes: Our machining centers and lathes offer precision that directly contributes to your success. With 80 years of experience in machine building, you get products specifically designed to meet the demands of complex production processes.

Technical Data

Features of HL (Hwacheon Lathes, conventional)

Steady Rest Carriage

Stability for Precise Results: The steady rest ensures maximum precision for long workpieces through optimal support. It reduces vibrations, improves surface quality, and enables precise machining even for demanding projects.

Powerful Gear Spindle

Maximum Power and Torque: Gear spindles deliver high torque, ideal for heavy-duty machining processes. The innovative oil-jet cooling system maintains a consistent temperature and ensures stable performance even during prolonged machining operations. Large spindle bearings and shaft diameters enhance rigidity and durability under high loads.

Flat Guides

Excellent Damping Properties: Box or flat guides effectively absorb vibrations from the machining process by transferring them into the machine bed due to their large contact surface. Hand-fitted and scraped by experienced staff, these guides ensure precision. Central oil lubrication provides continuous lubrication with bedway oil, while the Turcite coating on the sliding surface offers excellent emergency running properties. Machines with flat guides are more durable and can handle higher chip volumes. Thanks to these unique features, they are considered particularly powerful and reliable.