Over 80 years of detailed experience: Hwacheon combines traditional craftsmanship with modern technology. Our expertise in machine tool manufacturing ensures high production quality and continuous innovation for future-proof concepts in the German market.

MEGA-130

Category

Cycle-Controlled LathesMachine series

MEGA - BaureiheAvailable with

- Sinumerik One

- Siemens 828D

- Fanuc 31i

- Fanuc 0i Plus

Size of MEGA-130

| Max. cutting diameter | mm | 920 |

| Chuck-Size | mm | 810 |

| Swing over bed | mm | 1300 |

Tradition Meets Modernity

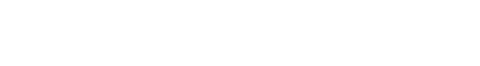

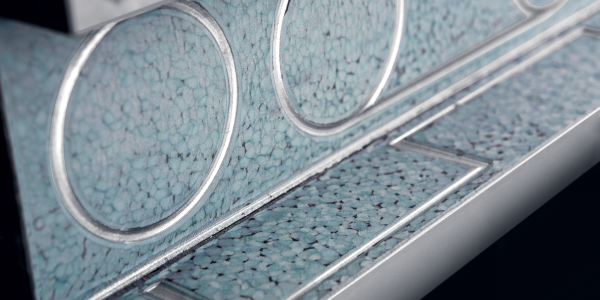

Flat Guides

Excellent Damping Properties: Box or flat guides effectively absorb vibrations from the machining process by transferring them into the machine bed due to their large contact surface. Hand-fitted and scraped by experienced staff, these guides ensure precision. Central oil lubrication provides continuous lubrication with bedway oil, while the Turcite coating on the sliding surface offers excellent emergency running properties. Machines with flat guides are more durable and can handle higher chip volumes. Thanks to these unique features, they are considered particularly powerful and reliable.

Why choose us?

Future-Proof Solutions

Innovation in every machine: State-of-the-art technologies shape our machine concepts, based on the latest standards for turning and milling machines. You benefit from efficient solutions, customized to your requirements.

Tradition Meets Modernity

Over 80 years of detailed experience: Hwacheon combines traditional craftsmanship with modern technology. Our expertise in machine tool manufacturing ensures high production quality and continuous innovation for future-proof concepts in the German market.

In-House Quality

Quality is created here: With our own manufacturing depth, including foundry and spindle production, we ensure durable and reliable machines. Quality and control go hand in hand to meet the German standards.

Technical Data

| Item | Unit | MEGA-130 |

|---|---|---|

| Spindle power | kW | 55 / 37 |

| Spindle speed | rpm | 40-630 |

| Spindle torque | Nm | 11376 |

| Rapid speed | m/min | 6 / - / 6 |

| Number of tools | 4 | |

| Max. cutting diameter | mm | 920 |

| Max. cutting length | mm | 3 (4, 5, 6, 7, 8) |

| Chuck-Size | mm | 810 |

| Swing over bed | mm | 1300 |

| Max. Bar size | mm | 155 (255, 320) |

| Coolant tank vol. | Liter | 220 |

Features of MEGA-130

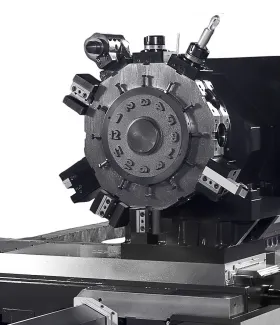

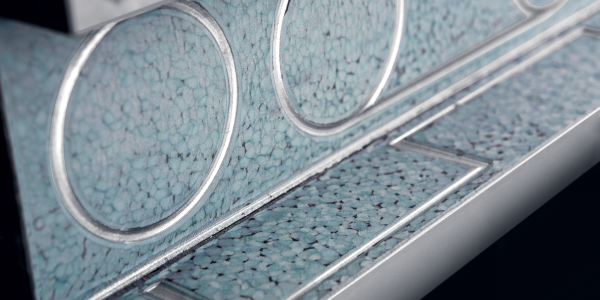

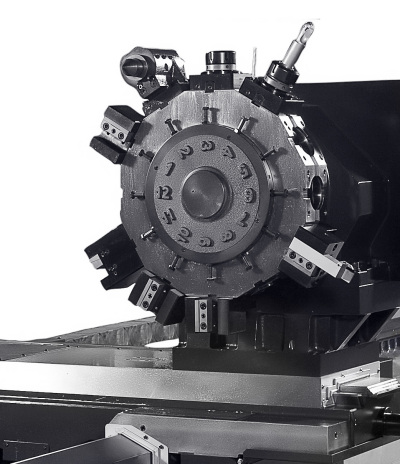

Turret

| Number of tools | 4 |

Driven Tools

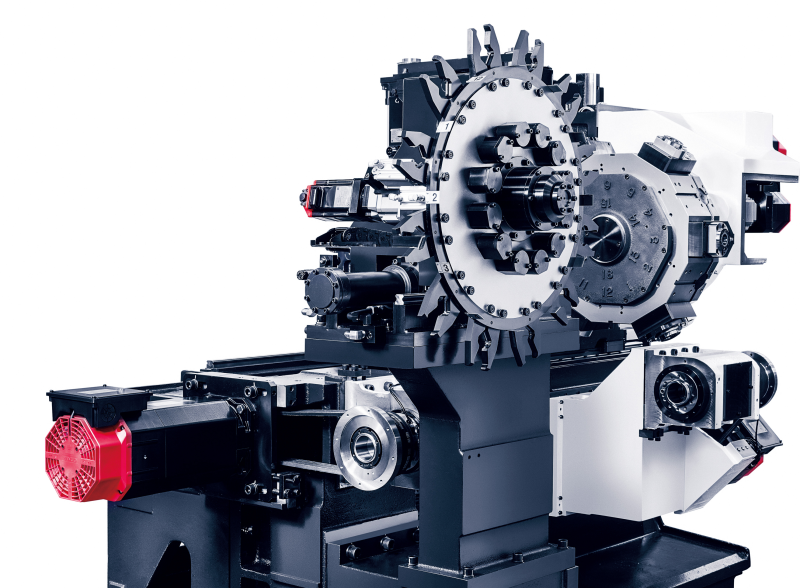

Precision and Versatility Combined: Driven tools on lathes significantly expand machining capabilities. They enable milling, drilling, and other processes directly on the lathe, reducing re-clamping operations and minimizing downtime. Using various tools in a single setup increases machining accuracy and boosts overall productivity.

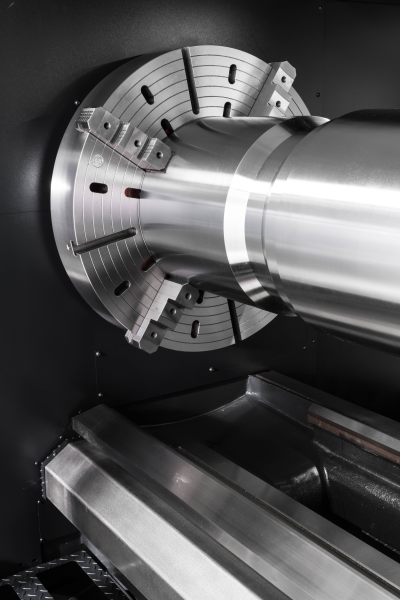

Clamping Technology

| Chuck-Size | mm | 810 |

Flat Guides

Excellent Damping Properties: Box or flat guides effectively absorb vibrations from the machining process by transferring them into the machine bed due to their large contact surface. Hand-fitted and scraped by experienced staff, these guides ensure precision. Central oil lubrication provides continuous lubrication with bedway oil, while the Turcite coating on the sliding surface offers excellent emergency running properties. Machines with flat guides are more durable and can handle higher chip volumes. Thanks to these unique features, they are considered particularly powerful and reliable.

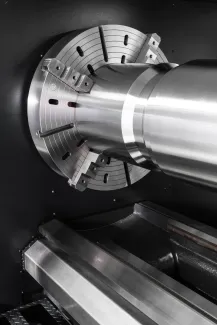

Powerful Gear Spindle

High-Torque Drives for Heavy Machining: Lathes with gear spindles offer significantly higher torque than those with motor spindles. By selecting the appropriate gear ratio, torque can be optimally utilized within the speed range of the ideal cutting speed. Large spindle bearings and shaft diameters robustly absorb process forces and peaks, ensuring high durability. The gear stage can be conveniently selected via M-functions.

- Spindle power55 / 37kW

- Spindle speed40-630rpm

- Spindle torque11376Nm

Extra Large Hollow Spindle

Perfect for Tube Machining: BigBore lathes impress with their large hollow spindle diameter, allowing large workpiece diameters to be loaded or unloaded through the spindle or deeply clamped. They excel particularly in machining large tubes, utilizing pneumatic power chucks on both the front and rear sides of the spindle.

- Max. Bar sizeØ155 (255, 320)mm

Steady Rest Carriage

Stability for Precise Results: The steady rest ensures maximum precision for long workpieces through optimal support. It reduces vibrations, improves surface quality, and enables precise machining even for demanding projects.

High-Quality Pretensioned Ball Screws

Thermal Stability for Precision and Reliability: Pretensioned ball screws reliably and stably compensate for thermal expansion. This technology prevents unwanted elongation of the spindles, ensuring lasting precision and consistently high machining accuracy over extended operating periods.

Excellent Chip Disposal

Perfect Chip Removal for Your Machine!: Our innovative chip disposal systems reliably remove chips, reduce heat, and optimize machining. High-quality components ensure uninterrupted operation and maximum process reliability.

- Coolant tank vol.220Liter

Other features and options

Tailstock, Sinumerik One, Siemens 828D, Fanuc 31i, Fanuc 0i Plus, Automatic Tool Changer, Chip Conveyor, Work table, Workspace, Peripherals and accessories, Machine SizeMEGA-72

| Max. cutting diameter | mm | 470 |

| Chuck-Size | mm | 355 |

| Swing over bed | mm | 720 |

MEGA-110

| Max. cutting diameter | mm | 1100 |

| Swing over bed | mm | 1100 |

MEGA-130

| Max. cutting diameter | mm | 920 |

| Chuck-Size | mm | 810 |

| Swing over bed | mm | 1300 |