Over 80 years of detailed experience: Hwacheon combines traditional craftsmanship with modern technology. Our expertise in machine tool manufacturing ensures high production quality and continuous innovation for future-proof concepts in the German market.

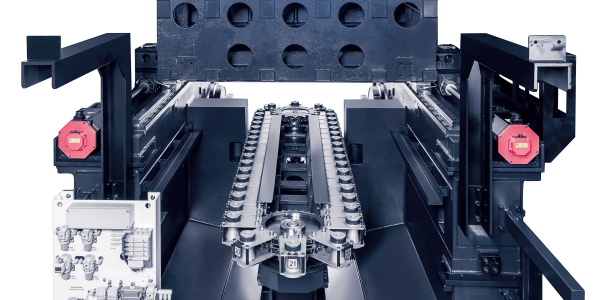

M4-5AX

Category

5 Axis Machining CentersMachine series

M - BaureiheAvailable with

- Sinumerik One

- Harmony

- Fanuc 31i

- Heidenhain TNC 640

Size of M4-5AX

- Axis-Stroke (X / Y / Z)950 / 1.000 / 650mm

- Table sizeØ800 x 630mm

- Tool shankBBT-50No unit

Tradition Meets Modernity

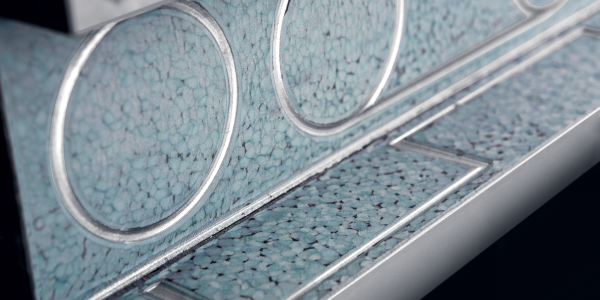

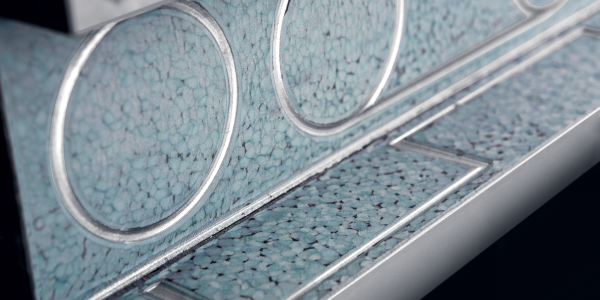

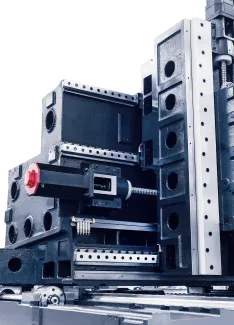

Flat Guides

Excellent Damping Properties: Box or flat guides effectively absorb vibrations from the machining process by transferring them into the machine bed due to their large contact surface. Hand-fitted and scraped by experienced staff, these guides ensure precision. Central oil lubrication provides continuous lubrication with bedway oil, while the Turcite coating on the sliding surface offers excellent emergency running properties. Machines with flat guides are more durable and can handle higher chip volumes. Thanks to these unique features, they are considered particularly powerful and reliable.

Dynamic Linear Guides

Speed and Dynamics Combined: Linear roller guides provide high dynamics and rapid traverse speeds. The workpiece weight is transferred linearly to the rollers, which must withstand enormous pressure at contact points. Therefore, we exclusively use linear roller guides from renowned manufacturers.

Why choose us?

Performance in Focus

Power for your production: Our machines are designed for maximum productivity and availability. Top-class engineering and craftsmanship provide you with a crucial competitive advantage – all for your business success.

In-House Quality

Quality is created here: With our own manufacturing depth, including foundry and spindle production, we ensure durable and reliable machines. Quality and control go hand in hand to meet the German standards.

Technical Data

| Item | Unit | M4-5AX | M4-5AX (iTNC 640) |

|---|---|---|---|

| Axis-Stroke (X / Y / Z) | mm | 950 / 1.000 / 650 | |

| Table size | mm | 800 x 630 | |

| Table load | kg | 1200 | |

| Spindle power | kW | 30 (55) | 1 |

| Spindle speed | rpm | 12.000 (8.000) | |

| Spindle torque | Nm | 420 (1.009) | 1 |

| Feedrate | m/min | 24 / 24 / 24 | 1 - 24 |

| Rapid speed | m/min | 36 / 36 / 30 | |

| Tool shank | No unit | BBT-50 | 1 |

| Number of tools | Amount | 30 (60) | |

| Machine weight | kg | 28000 | |

| NC-Control | No unit | FANUC 31i-B5 | Heidenhain iTNC 640 |

Features of M4-5AX

Flat Guides

Excellent Damping Properties: Box or flat guides effectively absorb vibrations from the machining process by transferring them into the machine bed due to their large contact surface. Hand-fitted and scraped by experienced staff, these guides ensure precision. Central oil lubrication provides continuous lubrication with bedway oil, while the Turcite coating on the sliding surface offers excellent emergency running properties. Machines with flat guides are more durable and can handle higher chip volumes. Thanks to these unique features, they are considered particularly powerful and reliable.

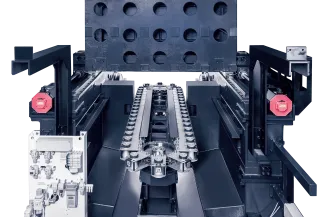

Work table

| Table size | mm | 800 x 630 | |

| Table load | kg | 1200 | |

Dynamic Linear Guides

Speed and Dynamics Combined: Linear roller guides provide high dynamics and rapid traverse speeds. The workpiece weight is transferred linearly to the rollers, which must withstand enormous pressure at contact points. Therefore, we exclusively use linear roller guides from renowned manufacturers.

Automatic Tool Changer

| Tool shank | No unit | 1 - BBT-50 | |

| Number of tools | Amount | 30 (60) | |

Peripherals and accessories

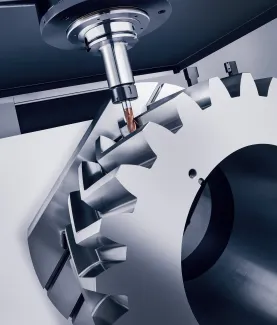

HSC Spindle

Ultimate Precision, Maximum Speed: HSC spindles utilize high speeds and fast feeds to achieve higher material removal rates despite reduced cutting depth. This combination lowers machining forces and minimizes heat input through rapid chip removal. Primarily used in tool and mold making, they meet the highest standards for surface quality, dimensional accuracy, and contour fidelity.

- Spindle power30 (55)kW

- Spindle speed12.000 (8.000)rpm

- Spindle torque420 (1.009)Nm

- Tool shankBBT-50No unit

Internal Coolant Supply

ICS Makes the Difference!: The internal coolant supply (ICS) delivers coolant directly to the cutting edge, optimizing lubrication and chip removal. It boosts productivity, extends tool life, and enhances process reliability.

High-Quality Pretensioned Ball Screws

Thermal Stability for Precision and Reliability: Pretensioned ball screws reliably and stably compensate for thermal expansion. This technology prevents unwanted elongation of the spindles, ensuring lasting precision and consistently high machining accuracy over extended operating periods.

Excellent Chip Disposal

Perfect Chip Removal for Your Machine!: Our innovative chip disposal systems reliably remove chips, reduce heat, and optimize machining. High-quality components ensure uninterrupted operation and maximum process reliability.

Other features and options

BBT-50 / BT-50, Sinumerik One, Harmony Interface, Fanuc 31i, Heidenhain TNC 640, Chip Conveyor, Workspace, Tool measuring, Machine SizeVideo gallery

M1-5AX

- Axis-Stroke (X / Y / Z)750 / 500 / 450mm

- Table sizeØ300mm

- Tool shankBBT-40

M2-5AX

- Axis-Stroke (X / Y / Z)750 / 650 / 500mm

- Table sizeØ500+30°-120°mm

- Tool shankBBT-40

M3-5AX

- Axis-Stroke (X / Y / Z)750 / 900 / 550mm

- Table sizeØ700mm

- Tool shankBBT-40No unit

M4-5AX

- Axis-Stroke (X / Y / Z)950 / 1.000 / 650mm

- Table sizeØ800 x 630mm

- Tool shankBBT-50No unit

-->

-->