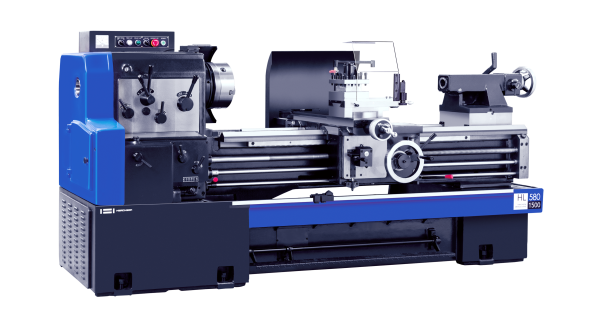

HL - Series

High-quality conventional lathes with hand-scraped guideways

HL (Hwacheon Lathes, conventional)

Conventional lathes - Made in South Korea

The HL are conventional lathes from South Korea (content incomplete).

Conventional Lathes

-->

| Item | Unit | A600 | AF-16 | AF-4 | APS A1000 alpha | AWC 20 | AWC 8 | C1 | C2 | CUTEX-160A | CUTEX-160B | CUTEX-180A | CUTEX-180AL | CUTEX-180B | CUTEX-180BL | CUTEX-240A | CUTEX-240B | CUTEX-240C | D2-5AX | D3-5AX | GR-10 | GR-5 | H6 | H8 | HL-380 | HL-460 | HL-580 | HL-580 | HL-630 | HL-720 | HL-950 | HMP 2200 | HMP 300 | HMP 700 | HMP ◻400 (for 1 machine) | HMP ◻400 (for 2 machine) | HMP ◻500 (for 1 machine) | HMP ◻500 (for 2 machines) | HMP ◻630 (for 2 machine) | HMP ◻630 Heavy (for 1 machine) | HMP ◻630 Heavy (for 2 machines) | HMP ◻800 (for 1 machine) | HMP ◻800 (for 2 machine) | HMP ◻800 Heavy (for 1 machine) | HMP ◻800 Heavy (for 2 machines) | HMP-100 | HMP-700 | HMTH-1100 | Hi-ECO 31 (4X-1200) | Hi-ECO 31 (4X-600) | Hi-M G1 | Hi-M G2+ | Hi-TECH 200A | Hi-TECH 200AL | Hi-TECH 200B | Hi-TECH 200BL | Hi-TECH 200C | Hi-TECH 200CL | Hi-TECH 230A | Hi-TECH 230AL | Hi-TECH 230AXL | Hi-TECH 230B | Hi-TECH 230BL | Hi-TECH 230BXL | Hi-TECH 230C | Hi-TECH 230CL | Hi-TECH 230CXL | Hi-TECH 350A | Hi-TECH 350AL | Hi-TECH 350B | Hi-TECH 350BL | Hi-TECH 450A | Hi-TECH 450AL | Hi-TECH 450AXL | Hi-TECH 450AXXL | Hi-TECH 450B | Hi-TECH 450BL | Hi-TECH 450BXL | Hi-TECH 450BXXL | Hi-TECH 450C | Hi-TECH 450CL | Hi-TECH 450CXL | Hi-TECH 450CXXL | Hi-TECH 550A | Hi-TECH 550A (v22) | Hi-TECH 550AL | Hi-TECH 550AL (v22) | Hi-TECH 550AXL | Hi-TECH 550B | Hi-TECH 550BB | Hi-TECH 550BBL | Hi-TECH 550BBXL | Hi-TECH 550BL | Hi-TECH 550BXL | Hi-TECH 650A | Hi-TECH 650AL | Hi-TECH 650AXL | Hi-TECH 650B | Hi-TECH 650BL | Hi-TECH 650BXL | Hi-TECH 700 | Hi-TECH 700BB | Hi-TECH 700BB+ | Hi-TECH 750A | Hi-TECH 750AL | Hi-TECH 750AXL | Hi-TECH 750B | Hi-TECH 750BL | Hi-TECH 750BXL | Hi-TECH 850 | Hi-TECH 850BB | Hi-TECH 850BB+ | Hi-TECH 850BB+L | Hi-TECH 850BB+XL | Hi-TECH 850BBL | Hi-TECH 850BBXL | Hi-TECH 850L | Hi-TECH 850XL | HiREX-4000 | HiREX-5000 | HiT-360D | HiT-400 | HiT-400L | L1-1500 | L1-2500 | L2-2500 | L2-3000 | L3 | M1-5AX | M2-5AX | M3-5AX | M4-5AX | M4-5AX (iTNC 640) | MEGA II 160 | MEGA II 200 | MEGA II 260 | MEGA-100 | MEGA-110 | MEGA-130 | MEGA-72 | MEGA-T130 | SIRIUS-1050 | SIRIUS-1250 | SIRIUS-1350 | SIRIUS-1750 | SIRIUS-2500 | SIRIUS-2500 5AX | SIRIUS-5AX | SIRIUS-7040 | SIRIUS-7050 | SIRIUS-850 | SIRIUS-UL+ | SIRIUS-UM | SIRIUS-UM+ | SIRIUS-UX | T2 | TTC-10 | UH 500 | VESTA-1000 | VESTA-1000 TEST | VESTA-1000+ | VESTA-1050B | VESTA-1300 | VESTA-1300+ | VESTA-1300B | VESTA-1300B+ | VESTA-1650 | VESTA-2000 | VESTA-500T | VESTA-610D | VESTA-650T | VESTA-660 | VESTA-850B | VT-1150+ | VT-1650 | VT-2000 | VT-2000M (Long type) | VT-450 | VT-450 2SP | VT-550 | VT-550 2SP | VT-650 | VT-650 2SP | VT-650 YMC | VT-950+ | i2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Axis-Stroke (X / Y / Z) | mm | 600 / 600 / 800 | 2600 / 1600 / 1500 | 565 / 645 / 645 | 3 | 4 | 5 | 310 / 100 / 700 | 360 / 120 / 700 | 170 / - / 335 | 170 / - / 335 | 205 / 110 / 380 | 220 / 110 / 580 | 205 / 110 / 380 | 220 / 110 / 580 | 215 / - / 700 | 215 / - / 700 | 215 / - / 700 | 650 / 500 / 500 | 800 / 650 / 575 | 3.020 / 970.5 | 3.020 / 970.5 | 1050 / 900 / 1000 | 1400 / 1150 / 1250 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 | 36 | 37 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 | 750 / 300 / 450 | 210 / - / 1270 | 210 / - / 670 | 750 / 600 / 350 | 1200 / 800 / 500 | 195 / - / 430 | 195 / - / 430 | 195 / - / 430 | 195 / - / 430 | 195 / - / 430 | 195 / - / 430 | 240 / 120 / 460 | 240 / 120 / 700 | 240 / 120 / 1200 | 240 / 120 / 460 | 240 / 120 / 700 | 240 / 120 / 1200 | 240 / 120 / 460 | 240 / 120 / 700 | 240 / 120 / 1200 | 280 / 120 / 790 | 280 / 120 / 1390 | 280 / 120 / 790 | 280 / 120 / 1390 | 280 / 120 / 790 | 280 / 120 / 1390 | 280 / 120 / 2280 | 280 / 120 / 3280 | 280 / 120 / 790 | 280 / 120 / 1390 | 280 / 120 / 2280 | 280 / 120 / 3280 | 280 / 120 / 790 | 280 / 120 / 1390 | 280 / 120 / 2280 | 280 / 120 / 3280 | 345 / - / 1150 | 83 | 345 / - / 2150 | 360 / 160 / 2200 | 345 / - / 3250 | 345 / - / 1150 | 345 / - / 1150 | 345 / - / 2150 | 345 / - / 3250 | 345 / - / 2150 | 345 / - / 3250 | 360 / 160 / 1200 | 360 / 160 / 2200 | 360 / 160 / 3300 | 360 / 160 / 1200 | 360 / 160 / 2200 | 360 / 160 / 3300 | 360 / - / 2050 | 360 / - / 2050 | 360 / - / 2050 | 430 / 200 / 2350 | 430 / 200 / 3350 | 430 / 200 / 4250 | 430 / 200 / 2350 | 430 / 200 / 3350 | 430 / 200 / 4350 | 485 / - / 2650 | 485 / 220 / 2650 | 485 / 220 / 2650 | 485 / 220 / 3650 | 485 / 220 / 5250 | 485 / 220 / 2650 | 485 / - / 2650 | 485 / - / 3650 | 485 / - / 5250 | 4000 / 520 / 570 | 5000 / 520 / 570 | 520 / 360 / 300 | 520 / 400 / 300 | 700 / 400 / 300 | 1500 / 950 / 500 | 2500 / 950 / 500 | 2500 / 950 / 500 | 300 / 1100 / 500 | 3000 / 1800 / 500 | 750 / 500 / 450 | 750 / 650 / 500 | 750 / 900 / 550 | 950 / 1.000 / 650 | 950 / 1.000 / 650 | 132 | 133 | 134 | 135 | 136 | 137 | 138 | 670 / - / 1100 | 2500 / 1050 / 850 | 2500 / 1250 / 750 | 2550 / 1350 / 750 | 3000 / 1750 / 800 | 3100 / 2300 / 900 | 3100 / 2300 / 900 | 750 / 650 / 520 | 1500 / 700 / 650 | 1500 / 700 / 650 | 2000 / 850 / 750 | 1050 / 600 / 550 | 750 / 500 / 450 | 750 / 500 / 450 | 1500 / 750 / 650 | 154 | 155 | 750 / 500 / 350 | 1000 / 550 / 550 | 1000 / 550 / 550 | 1.000 / 550 / 500 | 1050 / 600 / 600 | 1.300 / 670 / 650 | 1330 / 670 / 650 | 1300 / 670 / 650 | 1330 / 670 / 650 | 1650 / 750 / 675 | 2000 / 850 / 800 | 520 / 400 / 380 | 610 / 430 / 570 | 650 / 650 / 700 | 660 / 430 / 400 | 850 / 600 / 600 | 610 / - / 950 | 173 | 1750 / - / 1000 | 175 | 260 / - / 510 | 260 / - / 510 | 350 / - / 790 | 179 | 430 / - / 790 | 430 / - / 790 | 430 / 250 / 790 | 505 / - / 850 | 630 / 300 / 1160 |

| Pallet size | mm | 4 - 800 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Amount of pallets | 1 (2, 10) - 184 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Table load | kg | 1,400 - 15000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Spindle power | kW | 22/ 18.5 | 26 / 22 | 37 | 3 | 4 | 5 | 11 / 7.5 | 15 / 11 | 15 / 11 | 15 / 11 | 15 / 11 | 15 / 11 | 15 / 11 | 15 / 11 | 18.5 / 15 | 18.5 / 15 | 18.5 / 15 | 37 / 18,5 | 37 / 18,5 | 19 | 20 | 35 / 22 | 35/22 | 3.2 | 5.5 | 7.5 | 7.5 | 11 | 11 | 15 | 30 | 31 | 32 | 33 | 34 | 35 | 36 | 37 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 | 46 | 22/18.5 | 22/18.5 | 11.2 / 7.5 | 21 / 14 | 15 / 11 | 15 / 11 | 15 / 11 | 15 / 11 | 15 / 11 | 15 / 11 | 18.5 / 15 | 18.5 / 15 | 18.5 / 15 | 18.5 / 15 | 18.5 / 15 | 18.5 / 15 | 22 / 18.5 | 22 / 18.5 | 22 / 18.5 | 18.5 / 15 | 18.5 / 15 | 22 / 18.5 | 22 / 18.5 | 22 / 18.5 | 22 / 18.5 | 22 / 18.5 | 22 / 18.5 | 22 / 18.5 | 22 / 18.5 | 22 / 18.5 | 22 / 18.5 | 22 / 18.5 | 22 / 18.5 | 22 / 18.5 | 22 / 18.5 | 30 / 22 | 37 / 30 | 30 / 22 | 37 / 30 | 30/22 | 30 / 22 | 37/30 | 37 / 30 | 37 / 30 | 30 / 22 | 30/22 | 37 / 30 | 37 / 30 | 37 / 30 | 45 / 37 | 45 / 37 | 45 / 37 | 37 / 30 | 45 / 37 | 45 / 37 | 37 / 30 | 37 / 30 | 37 / 30 | 45 / 37 | 45 / 37 | 45 / 37 | 45 / 37 | 45 / 37 | 45 / 37 | 45 / 37 | 45 / 37 | 45 / 37 | 45 / 37 | 45 / 37 | 45 / 37 | 15 / 11 | 15 / 11 | 119 | 120 | 121 | 18.5 / 11 | 18.5 / 11 | 18.5 / 11 | 18.5 / 11 | 18.5 / 11 | 37 / 18.5 | 37 / 18.5 | 22 | 30 (55) | 131 | 132 | 140 / 100 | 140 / 100 | 23 / 18.5 | 55 / 37 | 55 / 37 | 18.5 / 15 | 23 / 18,5 | 30 / 25 | 30 / 25 | 30 / 25 | 30 / 25 | 30 / 25 | 18.5 / 11 | 22 / 18.5 | 15/11 | 15/11 | 30 / 25 | 37 / 18.5 | 18.5 / 11 | 37 / 18.5 | 35 / 25 | 15 / 11 | 18.5 / 15 | 24 | 18.5 / 11 | 18.5 / 11 | 18,5 | 18.5 / 15 | 18,5 | 162 | 18.5 / 11 | 18.5 | 18.5 / 11 | 18.5 | 11 | 15 / 11 | 18,5 / 11 | 15 / 11 | 18.5 / 15 | 55 / 45 | 45 | 174 | 175 | 22 / 18.5 | 22 / 18.5 | 22 / 18.5 | 22 / 18.5 | 22 / 18.5 | 22 / 18.5 | 22 / 18.5 | 30 / 22 | 22 / 15 |

| Spindle speed | rpm | 3 - 24000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Spindle torque | Nm | 3 - 98.1 / 79.5 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Feedrate | mm/min | 1 - 24000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Rapid speed | m/min | 3 - 60 / 60 / 60 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Tool shank | 2 - HSK-A63 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Number of tools | 40 | 60 (120, 180) | 40 (60) | 3 | 4 | 5 | 18 + 12 | 18 + 12 | 12 | 12 | 12 (24) | 12 (24) | 12 (24) | 12 (24) | 12 | 12 | 12 | 30 (40, 60) | 30 (40, 60) | 19 | 20 | 40 | 40 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 | 36 | 37 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 | 46 | 47 | 48 | 16 | 16 | 12 | 12 | 12 | 12 | 12 | 10 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 10 (12) | 10 (12) | 10 (12) | 10 (12) | 10 (12) | 12 | 10 (12) | 12 | 10 (12) | 10 (12) | 12 | 12 | 12 | 10 (12) | 10 (12) | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 24 | 24 | 21 | 21 | 21 | 30 | 30 | 30 | 30 | 30 (40) | 30 | 30 | 40 (60, 90) | 30 (60) | 30 (60) | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 (12) | 24 | 8 (40) | 40 (60) | 40 | 40 | 40 | 30 | 147 | 148 | 24 | 30 (40) | 24 | 30 | 40 | 12 (+12) | 2 x 12 | 24 | 24 | 158 | 30 | 24 | 30 | 30 | 30 | 30 / 24 | 30 | 30 | 24 | 24 | 30 | 20 | 24 | 12 (24) | 173 | 14 | 175 | 8 (10) | 8 (10) | 12 | 179 | 12 (10) | 12 | 12 (10) | 12 | 40 (80) | |

| Machine weight | kg | 3 - 81000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Coolant tank vol. | Liter | 93 - 1250 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Table size | mm | 2 - 700 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| NC-Control | 0 | 1 | Fanuc 0i-MF Plus | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 | 36 | 37 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 | 46 | Fanuc 31i-B | Fanuc 31i-B | 49 | 50 | 51 | 52 | 53 | 54 | 55 | 56 | 57 | 58 | 59 | 60 | 61 | 62 | 63 | 64 | 65 | 66 | 67 | 68 | 69 | 70 | 71 | 72 | 73 | 74 | 75 | 76 | 77 | 78 | 79 | 80 | 81 | 82 | 83 | 84 | 85 | 86 | 87 | 88 | 89 | 90 | 91 | 92 | 93 | 94 | 95 | 96 | 97 | 98 | 99 | 100 | 101 | 102 | 103 | 104 | 105 | 106 | 107 | 108 | 109 | 110 | 111 | 112 | 113 | 114 | 115 | 116 | 117 | 118 | 119 | 120 | 121 | Fanuc 0i-MF | Fanuc 0i-MF | Fanuc 0i-MF | Fanuc 0i-MF | Fanuc 0i-MF Plus | 127 | 128 | 129 | FANUC 31i-B5 | Heidenhain iTNC 640 | 132 | 133 | 134 | 135 | 136 | 137 | 138 | 139 | 140 | 141 | 142 | 143 | 144 | 145 | 146 | 147 | 148 | 149 | 150 | 151 | 152 | 153 | 154 | 155 | 156 | 157 | 158 | 159 | 160 | 161 | 162 | 163 | 164 | 165 | 166 | Fanuc 0i-MF | 168 | Fanuc 0i-MF | 170 | 171 | 172 | Fanuc 0i TF Plus (Fanuc 31i-B Plus) | Fanuc 31i-B / Siemens 840D | 175 | 176 | 177 | 178 | 179 | 180 | 181 | 182 | 183 | Fanuc 0i + Harmony | |

| Floor space | m | 1,775 x 1,200 - 184 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Max. cutting diameter | mm | 0 - 2500 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Max. cutting length | mm | 1.273 - 5100 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Chuck-Size | mm | 200 - 610 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Swing over bed | mm | 117 - ? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Max. Bar size | mm | 59 - 183 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Sub spindle speed | rpm | 0 - 6000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Sub spindle motor power | kW | 10 - 184 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Simultaneously controlled axis | Amount | 0 - 184 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Loading + Unloading time | second | 0 - 184 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Number of stations (stacker) | Amount | 10 / 14 - 184 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Max. Workpiece size (D x L) | mm | 100 - 184 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Min. Workpiece size (D x L) | mm | 21 - 184 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Max. stacked height per station | mm | 0 - 600 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Driven tools, max. Power | kW | 0 - 183 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Torque of driven tools | Nm | 0 - 386 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Axis-Stroke (X / Z / W) | mm | 174 - 184 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||