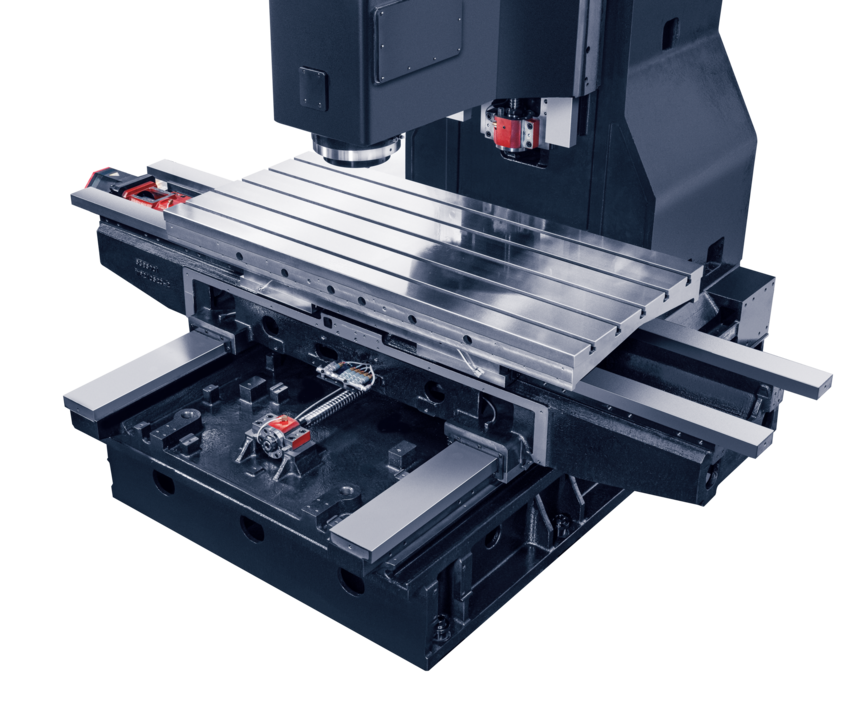

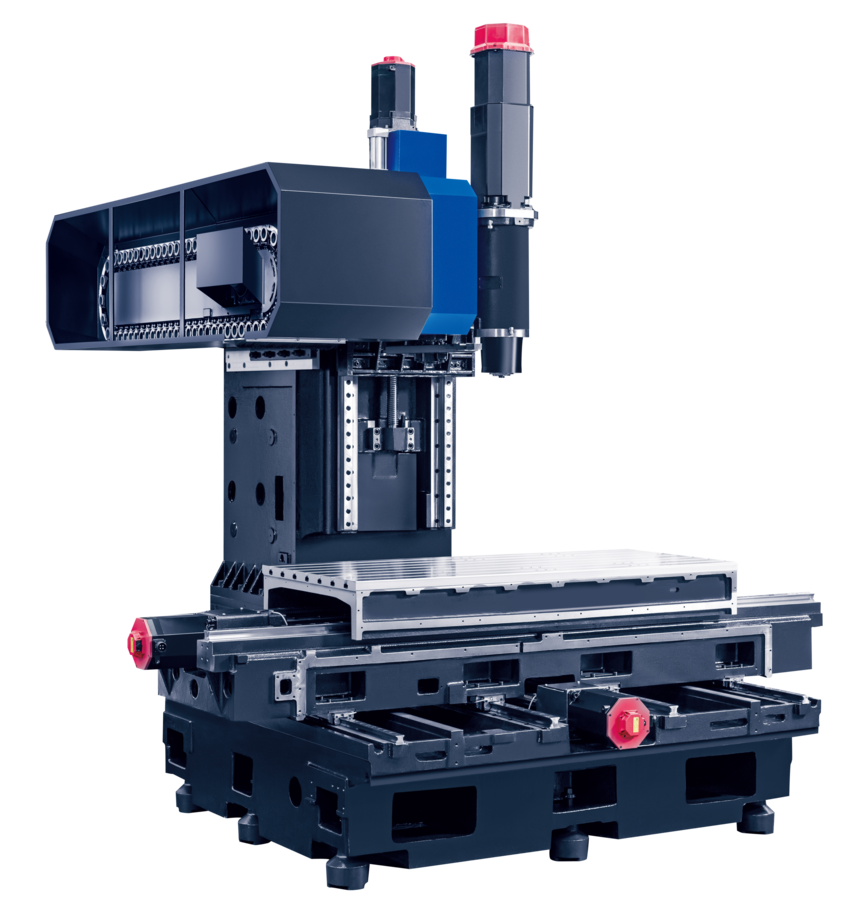

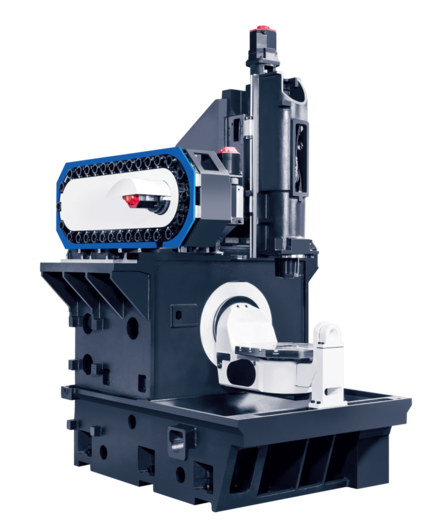

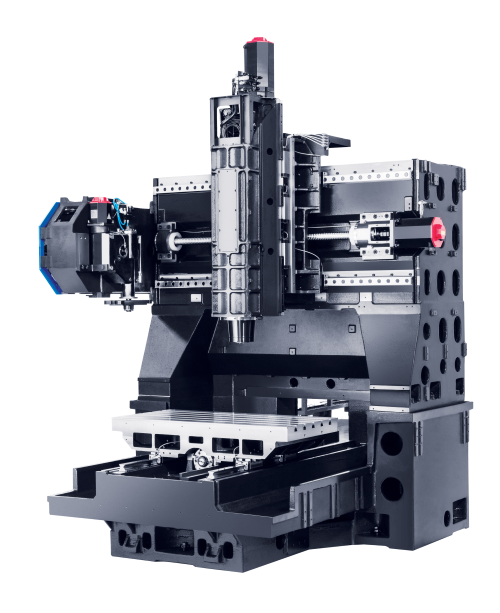

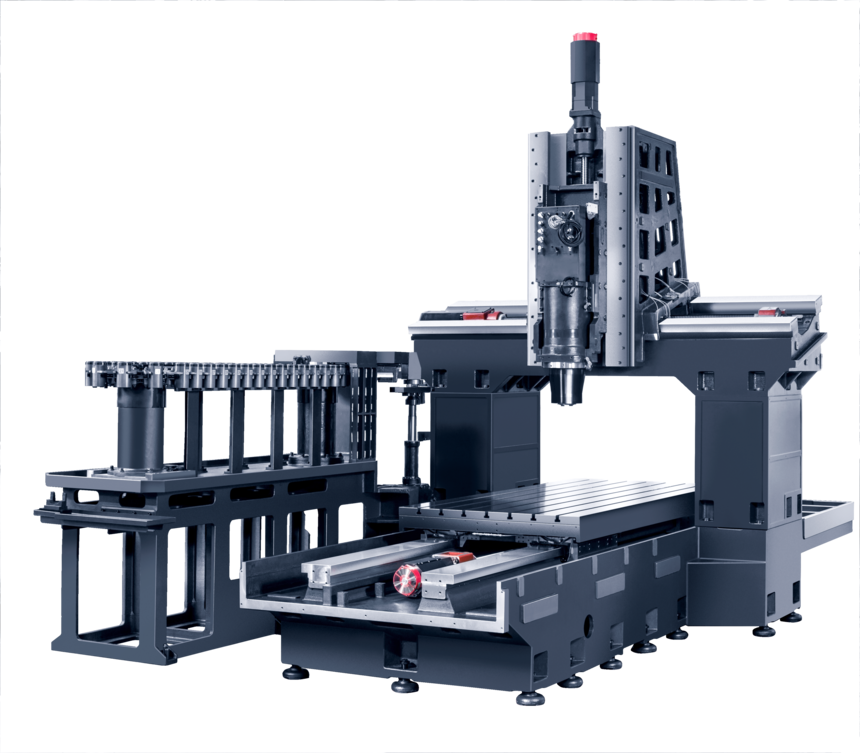

Vertical Machining Centers

Hwacheon offers a wide range of vertical machining centers specially developed for demanding tool and mold making as well as precision parts production. By combining high-quality machine components and modern machining software, we set new standards.